Stainless steel corrugated expansion joint and rubber expansion joint functional distinction

Stainless steel corrugated expansion joint and rubber expansion joint functional distinction

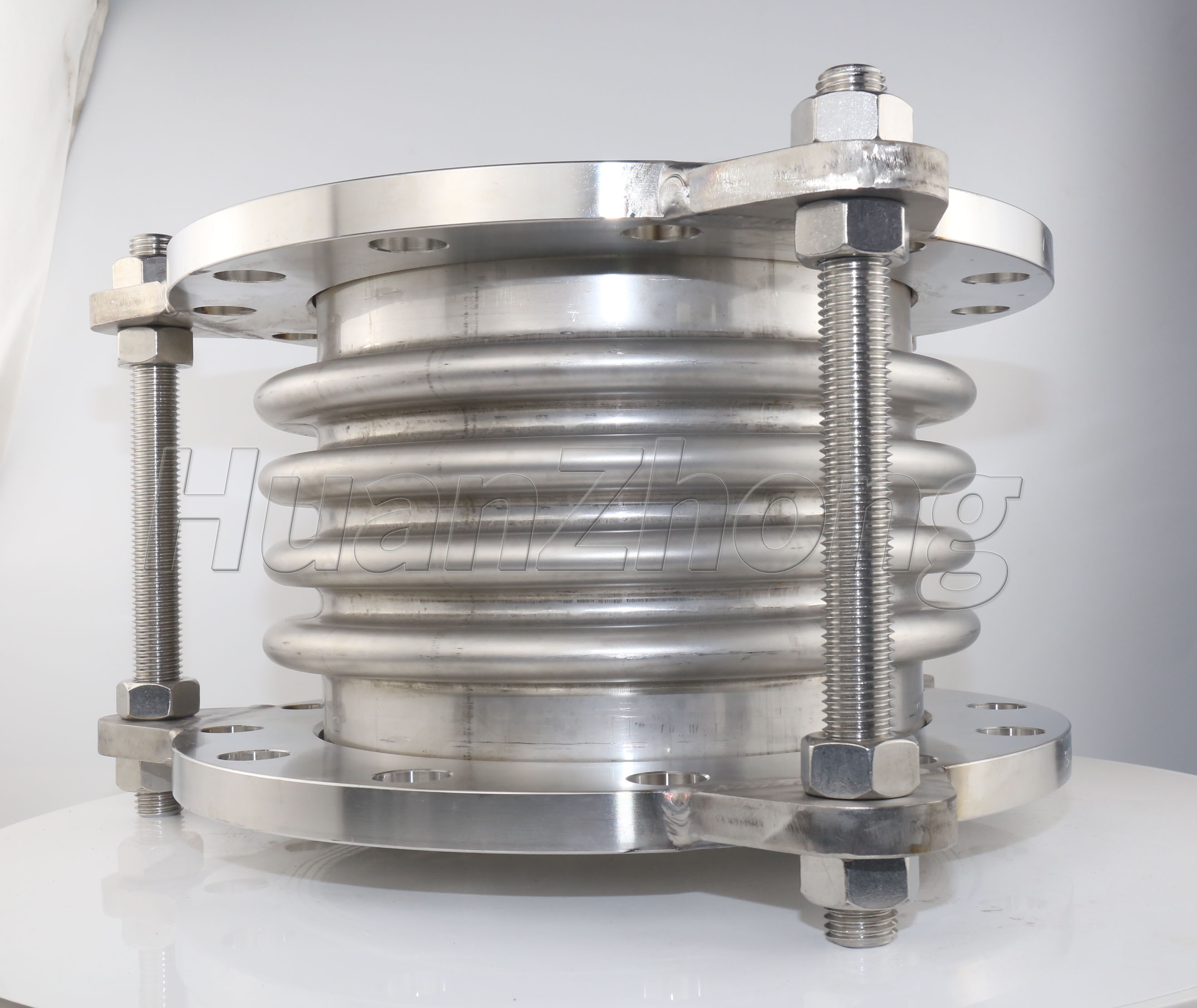

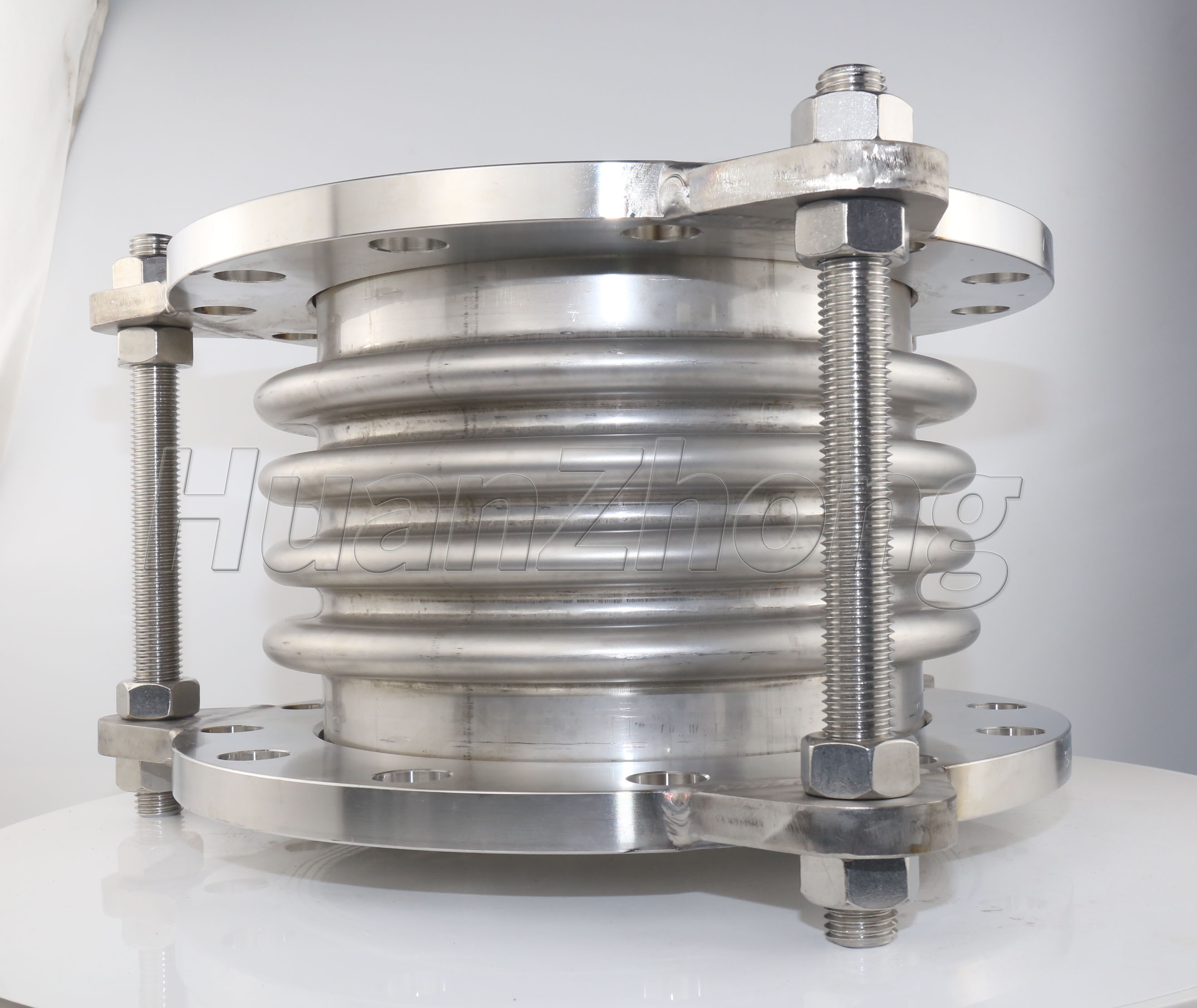

Stainless steel bellows expansion joint is also known as stainless steel bellows, stainless steel bellows compensator. The main products are stainless steel corrugated compensator for water and stainless steel corrugated expansion joint for ventilation. Mainly including flange, stainless steel corrugated and tie rod limit bolt. They are mainly used for vibration compensation and absorption of long transmission pipelines with oscillation characteristics, relying on their own corrugated absorbers have a good effect of vibration absorption and compensation displacement. The manufacturing materials of stainless steel bellows are mainly stainless steel 201, stainless steel 304 and stainless steel 316L, etc. According to different use environments, choose the right products to meet the pipelines of different media. Rectangular stainless steel corrugated pipe is mainly used for compensation connection of rectangular duct flue. It has good effect on the displacement and vibration caused by thermal expansion and contraction of high temperature pipeline. Our company produces stainless steel bellows with high quality materials and advanced welding process to ensure that no leakage and rupture will occur in the process of use.

There are two kinds of rubber expansion joints, one is rubber joint and the other is rubber duct corrugated compensator expansion joint. Rubber joints are used as accessories for pipeline vibration and noise reduction. It has a good effect on the displacement and vibration of the pipeline. The steel wire reinforcement layer inside the bendable rubber joint product can be used as tensile explosion-proof material, which makes the rubber joint more solid without affecting the performance. Rubber corrugated expansion joints are mainly used as air duct compensators with FUB, FVB, FDZ, etc. The rubber compensator consists of an insulating layer inside the steel skeleton and a corrugated outer corrosion-resistant rubber layer. There are mainly two kinds of shapes, round and square. The rubber duct compensator is mainly used for the damping compensation of coal powder duct or air duct, which is generally more effective. Rubber duct compensator is highly corrosion resistant and has good effect on desulfurization and corrosive media dust removal.

Stainless steel corrugated compensator can be used as high temperature resistant corrugated compensator, which has good effect on higher temperature use environment. The general use temperature of rubber joints is 150℃, and the use temperature of rubber duct compensator is generally below 500℃, so rubber joints and duct rubber compensators are not as widely used as stainless steel corrugated compensators in the use temperature range, but rubber joints and duct rubber compensators are good choices when used in low temperature corrosive media, and the general corrosion resistance of duct rubber compensators and rubber joints is better than Stainless steel corrugated expansion joints, and will have the same design life without material fatigue and other states. Therefore, in desulfurization projects, flexible rubber joints have great advantages compared with stainless steel corrugated compensators, but the rubber joints are made of composite materials in wear resistance, but the performance is not as good as stainless steel corrugated compensators with wear resistant guide bush.