How to test the safety of 304 stainless steel expanders?

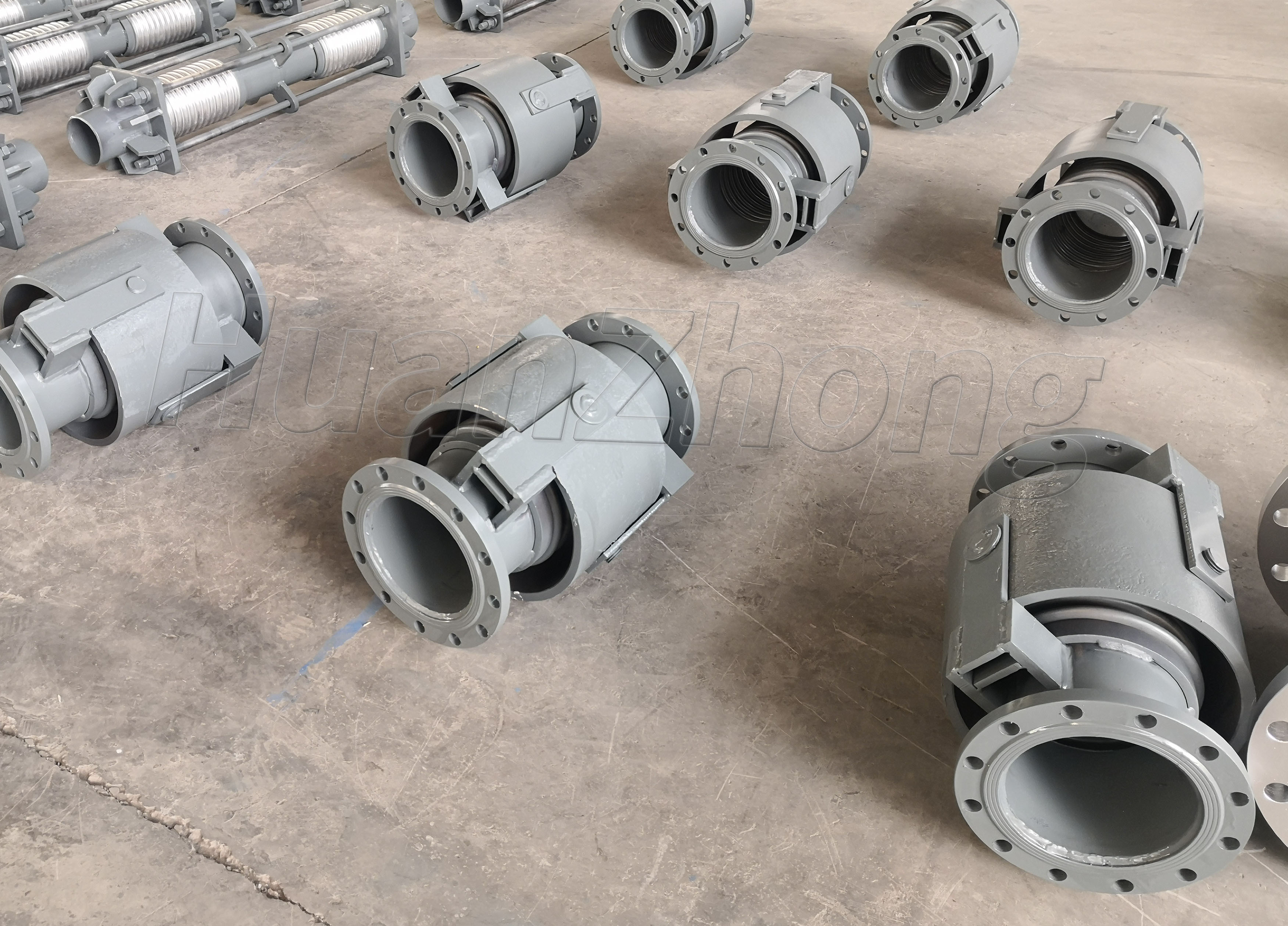

How to test the safety of 304 stainless steel expanders? Testing the safety of 304 stainless steel expanders is an important step to ensure their reliability and performance in various applications. Stainless steel expanders, commonly used in industries such as oil and gas, chemical, and manufacturing, are designed to withstand internal pressure and movement in piping systems. Here are some methods to test their safety:

Pressure Testing: One of the primary tests to assess the safety of stainless steel expanders is pressure testing. This involves subjecting the expander to internal pressure at a level higher than its maximum operating pressure. The test pressure is typically calculated based on design standards and safety factors. The expanders are monitored for leaks, bulges, or any signs of failure during the pressure test.

Leak Testing: Leak testing is conducted to ensure that the stainless steel expanders have proper sealing capabilities. Various methods can be employed, such as hydrostatic testing or pneumatic testing. In hydrostatic testing, the expander is filled with a liquid, and pressure is applied to check for any leakage. In pneumatic testing, compressed air or another gas is used instead of a liquid. The expanders are carefully inspected for leaks or any abnormal pressure drops.

Fatigue Testing: Stainless steel expanders are subjected to cyclic loading during their operation, which can lead to fatigue failure over time. Fatigue testing evaluates the expander's resistance to repeated pressure loading. This test applying alternating cycles of pressure to simulate operational conditions. The expanders are monitored for any signs of cracking or structural deformation during the fatigue test.

Corrosion Resistance Testing: 304 stainless steel is known for its excellent corrosion resistance. However, to ensure its long-term performance, corrosion resistance testing is performed. This test involves exposing the expanders to corrosive environments, such as saltwater or specific chemicals, and monitoring for any signs of corrosion or material degradation. Various methods like salt spray testing or immersion testing can be used to assess corrosion resistance.

Material Analysis: To further ensure the safety of the 304 stainless steel expanders, material analysis is conducted. This involves testing the chemical composition, mechanical properties, and microstructure of the steel. Material analysis helps verify that the stainless steel used meets the required standards and has the desired properties for safe operation.

Compliance with Standards: Stainless steel expanders should comply with industry standards and guidelines, such as those set by the Expansion Joint Manufacturers Association (EJMA). These standards provide guidelines for design, materials, fabrication, and testing. Ensuring compliance with these standards is essential to guarantee the safety and performance of the expanders.

Regular testing and inspection are necessary to monitor the safety of stainless steel expanders throughout their service life. Periodic checks for signs of wear, fatigue, corrosion, or any other potential issues should be conducted. Proper maintenance practices, including cleaning, lubrication, and inspection, should be followed to maximize the safety and longevity of the expanders.

In conclusion, testing the safety of 304 stainless steel expanders is crucial to ensure their reliability and performance. Pressure testing, leak testing, fatigue testing, and corrosion resistance testing are essential methods to evaluate their safety. Material analysis and compliance with industry standards further contribute to the overall safety of the expanders. Regular inspection and maintenance practices are necessary to monitor their safety during their service life.