Axial External Pressure Corrugated Expansion Joint Compensator Pre-Installation Preparation.

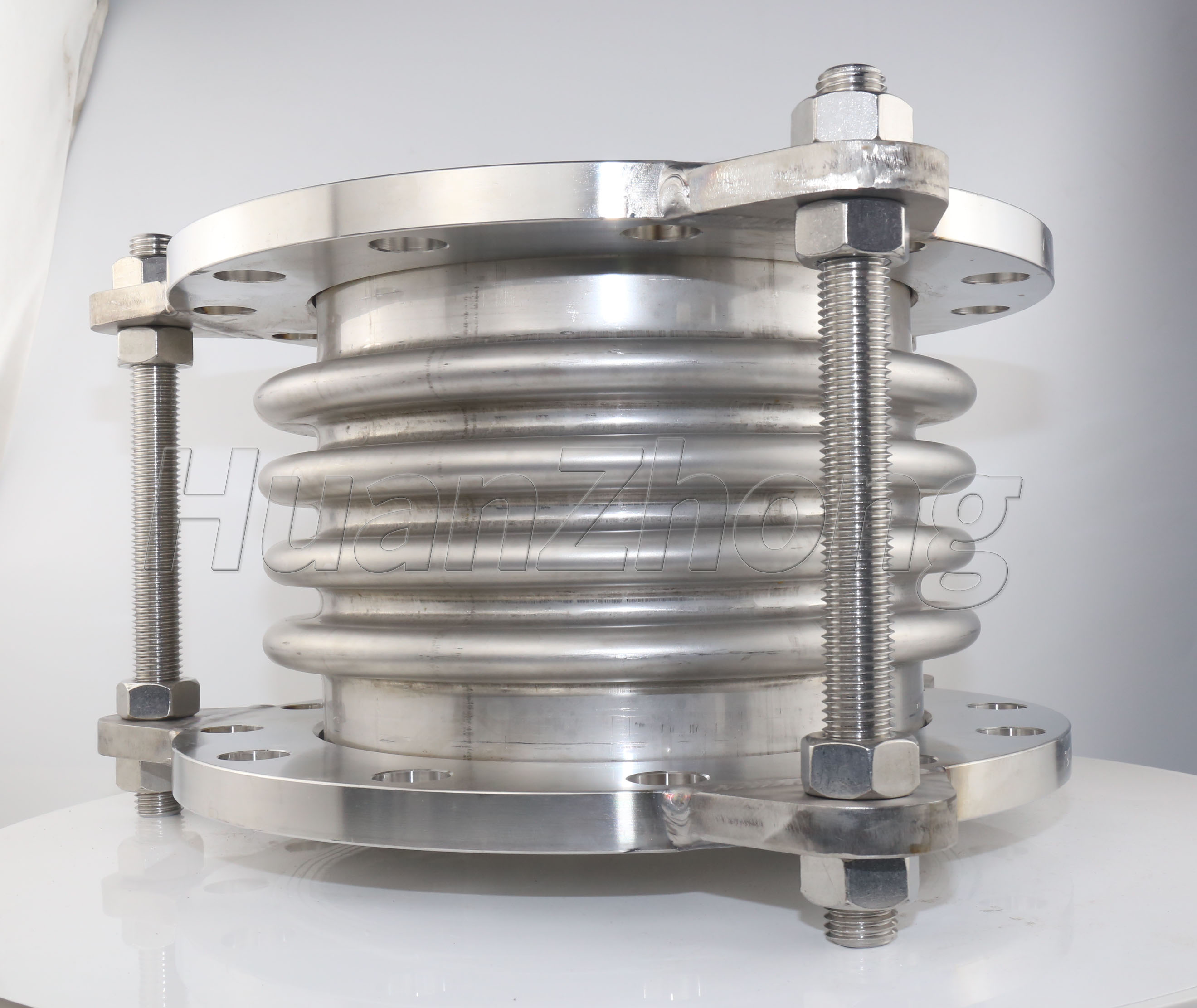

Axial External Pressure Corrugated Expansion Joint Compensator Pre-Installation Preparation. The axial external pressure corrugated expansion joint compensator is a vital component in piping systems, designed to accommodate axial movements and absorb external pressures. Proper pre-installation preparation is essential to ensure a successful installation and optimal performance of the compensator. This article will provide a comprehensive guide on the pre-installation preparation for an axial external pressure corrugated expansion joint compensator.

Review Specifications: Before starting the pre-installation process, it is vital to review the specifications and requirements provided by the manufacturer. This includes reviewing the compensator's dimensions, material specifications, pressure ratings, and temperature limitations. Understanding these specifications will ensure that the compensator is suitable for the intended application.

Inspection: Thoroughly inspect the compensator upon delivery to ensure it is free from any visible defects or damages. Check for signs of corrosion, dents, or any discrepancies that may affect its performance. If any issues are identified, contact the manufacturer or supplier for resolution before proceeding with the installation.

Plan Installation Location: Determine the exact location where the compensator will be installed within the piping system. Consider factors such as accessibility, proximity to other components, and any necessary supports or restraints. Ensure that there is sufficient space for the compensator to accommodate its anticipated movement.

Alignment: Proper alignment of the compensator is crucial for its performance and longevity. Ensure that the piping system is properly aligned before installing the compensator to minimize any additional strains or stresses. Use alignment tools or techniques to ensure proper alignment at both ends of the compensator.

Connectors and Flanges: Examine the connectors and flanges that will be utilized to connect the compensator to the piping system. Ensure that they are appropriate for the specified pressures, temperatures, and materials. Check for any damages, leaks, or alignment issues with these components, and resolve any issues before installation.

Pre-Installation Cleaning: Thoroughly clean the pipeline ends where the compensator will be installed. Remove any debris, rust, or other contaminants that may interfere with the sealing or connection. Use appropriate cleaning methods and materials recommended by the manufacturer to ensure a clean and suitable surface.

Lubrication: Apply a suitable lubricant to the connectors and flanges to facilitate easier installation. This helps to prevent binding or damage to the compensator during the installation process. Follow the manufacturer's recommendations for the type of lubricant to be used.

Installation Procedure: Follow the manufacturer's guidelines or specific installation instructions for the compensator. Ensure that the compensator is properly aligned, centered, and securely attached to the piping system. Use appropriate tools and torques to tighten the connectors and flanges to the specified requirements.

Inspection and Testing: After the installation is complete, conduct a thorough visual inspection of the compensator, connectors, and flanges. Check for any leaks, misalignment, or other installation issues. Perform pressure and/or leakage tests as recommended by the manufacturer or industry standards to verify the integrity and functionality of the compensator.

Proper pre-installation preparation is essential for the successful installation and optimal performance of axial external pressure corrugated expansion joint compensators. By following these steps, you can ensure that the compensator is installed correctly and in line with the manufacturer's recommendations. This will help to prevent issues such as leaks, faulty connections, or premature failures, ensuring a reliable and efficient piping system.