Definitions of Food-Grade Rubber Joints

Introduction:In the food and beverage industry, the use of materials that meet stringent safety and hygiene standards is paramount. Food-grade rubber joints play a critical role in ensuring the integrity of sanitary piping systems. This article provides an overview of the definitions and standards that govern food-grade rubber joints, emphasizing their significance in maintaining the quality and purity of food processing environments.

Compliance and Certification:Food-grade rubber joints are defined by their adherence to specific regulatory and industry standards that ensure they are suitable for use in contact with food products. These standards encompass criteria related to material composition, manufacturing practices, and performance characteristics. Components that come into direct or indirect contact with food must meet the requirements of organizations such as the FDA (Food and Drug Administration) in the United States, the European Food Safety Authority (EFSA), and other relevant regulatory bodies worldwide.

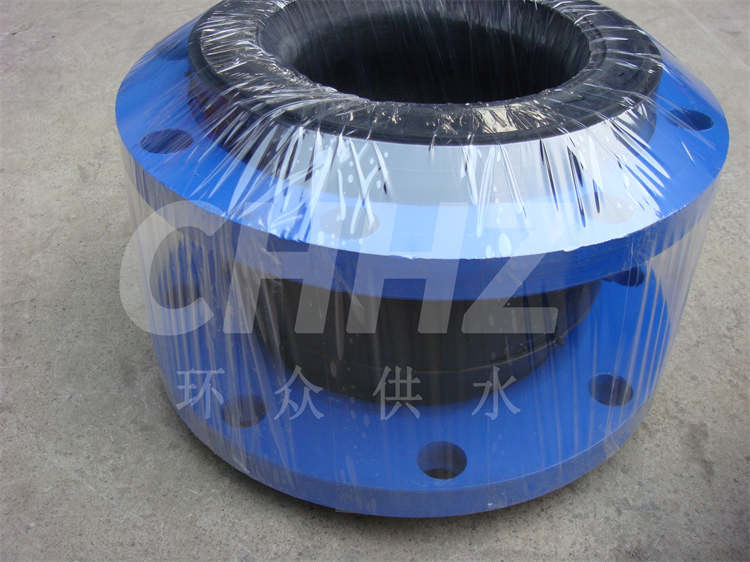

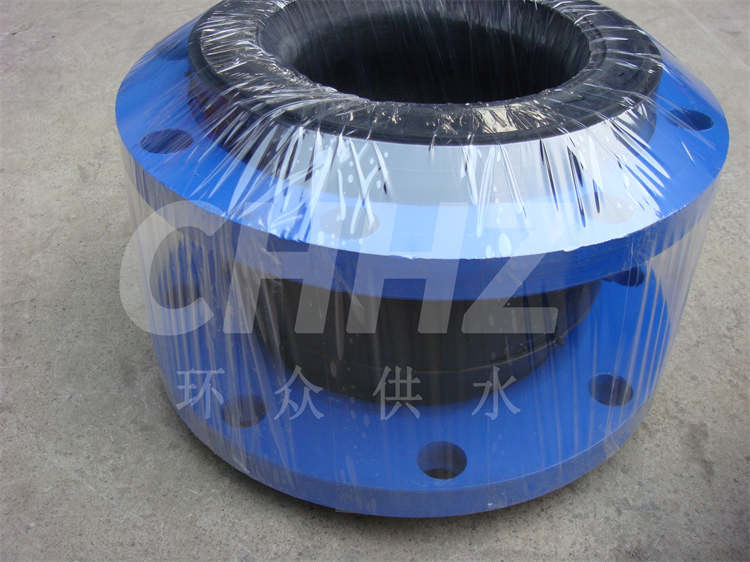

Material Composition:The definition of food-grade rubber joints includes the specification of materials that are deemed safe for use in food processing applications. These materials are typically non-toxic, non-leaching, and resistant to degradation from exposure to food substances, cleaning agents, and sanitizing solutions. Commonly used elastomers for food-grade rubber joints include silicone, EPDM (ethylene propylene diene monomer), and nitrile rubber, all of which are formulated to meet strict regulatory standards for food contact.

Hygienic Design:Food-grade rubber joints must exhibit features that promote hygienic operation and ease of cleaning. The design of the joints should minimize the presence of crevices, dead spaces, and areas where microbial growth or contamination could occur. Smooth, non-porous surfaces and seamless construction are essential characteristics that facilitate thorough cleaning and sanitation, thereby preventing the accumulation of food residues and microbial contaminants.

Temperature and Chemical Resistance:The definition of food-grade rubber joints also encompasses their ability to withstand a wide range of temperatures and exposure to various chemicals and cleaning agents commonly used in food processing facilities. The joints must maintain their physical properties and resistance to deterioration when subjected to cleaning protocols involving heat, steam, sanitizing agents, and detergents.

Traceability and Documentation:Food-grade rubber joints are often subject to stringent traceability and documentation requirements to ensure their safe usage in food applications. Manufacturers are expected to provide comprehensive documentation that verifies the compliance of materials and processes with applicable standards. This documentation typically includes material certifications, test reports, and compliance statements to demonstrate adherence to food safety regulations.

Conclusion:In conclusion, the definition of food-grade rubber joints encompasses a comprehensive set of criteria related to material safety, hygienic design, chemical resistance, and regulatory compliance. These criteria ensure that rubber joints used in food processing facilities are aligned with the stringent standards for food contact materials, thereby safeguarding the purity and safety of food products and contributing to the overall integrity of the food and beverage industry.