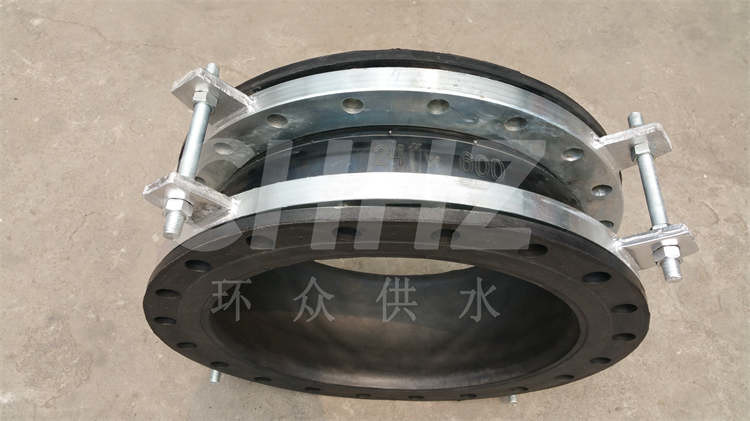

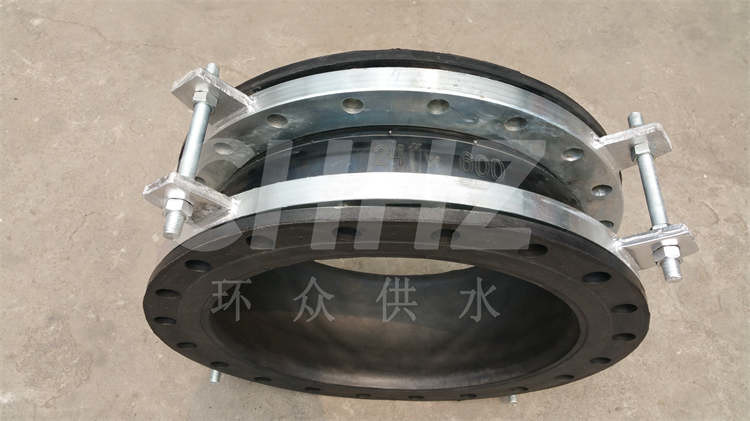

How to Insert Rubber Corrugated Hoses with Metal Fittings

Inserting rubber corrugated hoses with metal fittings is a critical process in various industries where flexible and resilient fluid transfer systems are required. The combination of rubber hoses and metal fittings allows for versatile and durable connections that can withstand a wide range of pressures, temperatures, and environmental conditions. In this article, we will discuss the essential steps and considerations involved in the proper insertion of rubber corrugated hoses with metal fittings, highlighting the techniques for achieving secure and reliable connections.

Preparation of Rubber Corrugated Hoses: Before the insertion process, it is vital to prepare the rubber corrugated hoses to ensure optimal flexibility and cleanliness. Inspect the hoses for any signs of damage, wear, or deformities, and trim them to the required length using appropriate cutting tools. Additionally, remove any debris, foreign particles, or contaminants from the hose's interior and exterior surfaces to prevent interference with the insertion process and to maintain the integrity of the system.

Selection of Metal Fittings: Select metal fittings that are compatible with the specifications of the rubber corrugated hoses and are designed to provide a secure and leak-free connection. Consider factors such as thread size, material compatibility, and sealing mechanisms to ensure the proper fit between the hoses and fittings. It is essential to verify that the metal fittings are free from defects, such as burrs or sharp edges, that could compromise the integrity of the rubber hoses during insertion.

Lubrication and Alignment: Apply a suitable lubricant to the exterior surface of the rubber corrugated hoses and the interior of the metal fittings to facilitate smooth insertion. Proper lubrication reduces friction and allows for easier maneuvering of the hoses onto the fittings. Align the metal fittings with the ends of the hoses, ensuring that the fitting threads and hose surfaces are aligned parallel to each other. This alignment is crucial for achieving a uniform and secure connection between the rubber hoses and metal fittings.

Insertion Technique: The insertion of rubber corrugated hoses with metal fittings requires a methodical approach to avoid damage to the hoses or fittings. Begin by gently coaxing the hose onto the fitting, using a twisting motion to gradually advance the hose onto the fitting threads. Avoid applying excessive force or bending the hose excessively, as this could cause deformation or damage to the hose structure. Continue the insertion process until the hose is fully seated on the metal fitting, ensuring that the connection is snug and secure.

Testing and Inspection: After inserting the rubber corrugated hoses with metal fittings, conduct thorough testing and inspection procedures to verify the integrity and leak-tightness of the connections. Perform pressure tests and visual inspections to check for any signs of leakage, deformation, or misalignment. Additionally, assess the flexibility and movement of the hose assembly to confirm that the insertion process has not impeded the performance of the system.

In conclusion, the insertion of rubber corrugated hoses with metal fittings involves meticulous preparation, selection of suitable fittings, lubrication, alignment, insertion techniques, and testing procedures. By following these guidelines, technicians and engineers can ensure the reliable and robust connectivity of rubber hoses with metal fittings, contributing to the efficient and safe operation of fluid transfer systems in diverse industrial applications.