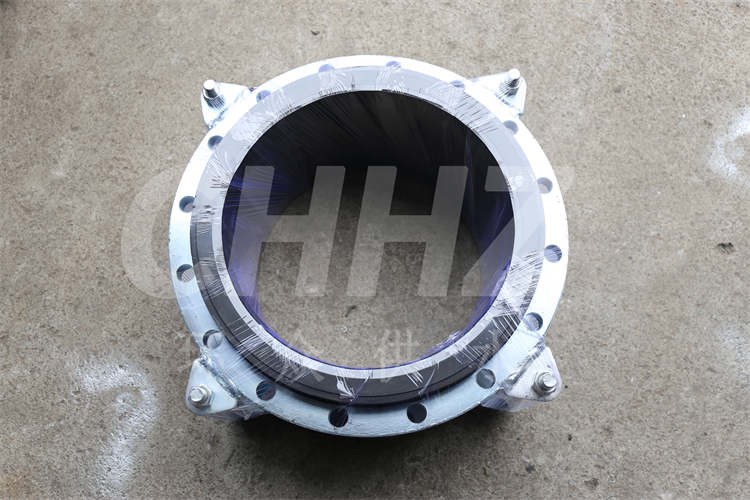

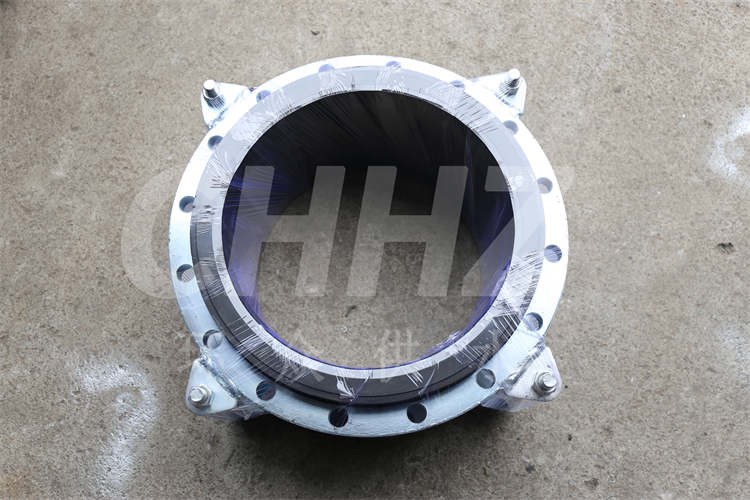

Rubber Expansion Joint Leakage in Water Tanks

Rubber expansion joints are commonly used in water tank systems to accommodate movement, absorb vibrations, and provide flexibility. However, issues such as leakage can arise if these components are not properly selected, installed, or maintained. This article aims to discuss the causes of rubber expansion joint leakage in water tanks and strategies to prevent and address this issue effectively.

Causes of Leakage:Rubber expansion joint leakage in water tanks can stem from various factors. Aging and deterioration of the rubber material due to prolonged exposure to water, chemicals, or harsh environmental conditions may compromise the joint's integrity, leading to leaks. Mechanical damage, improper installation, or inadequate anchoring can also contribute to joint failure and subsequent leakage. Furthermore, fluctuations in water pressure, temperature, and the presence of abrasive substances can exacerbate the wear and tear on expansion joints, potentially causing leakage over time.

Preventive Measures:To mitigate the risk of rubber expansion joint leakage in water tanks, preventive measures should be implemented. This includes the careful selection of high-quality, durable expansion joints that are specifically designed for water tank applications. Regular inspection and maintenance, including monitoring for signs of wear, corrosion, or deterioration, can help detect potential issues before they escalate into leaks. Proper installation techniques, such as ensuring correct alignment, adequate sealing, and appropriate anchoring, are critical in preventing leakage. Additionally, considering the operating conditions, including water temperature, pressure fluctuations, and the presence of chemicals, is essential in selecting expansion joints that can withstand these challenges.

Addressing Leakage:In the event of rubber expansion joint leakage in water tanks, prompt action is necessary to prevent further damage and safeguard the integrity of the tank system. Identifying the source of the leakage through thorough inspection and assessment is the first step. Subsequently, addressing the root cause, which could involve replacing worn or damaged expansion joints, repairing seals, or reinforcing anchoring mechanisms, is crucial in resolving the issue. It is essential to use high-quality replacement joints that are compatible with the specific requirements of the water tank system to ensure long-term performance and prevent future leakage incidents.

Conclusion:Rubber expansion joint leakage in water tanks can compromise system integrity, lead to water loss, and incur maintenance costs. By understanding the causes of leakage and implementing preventive measures, such as proper selection, installation, and maintenance of expansion joints, the risk of leakage can be minimized. Additionally, prompt action and effective solutions to address leakage are essential in preserving the functionality and reliability of water tank systems.