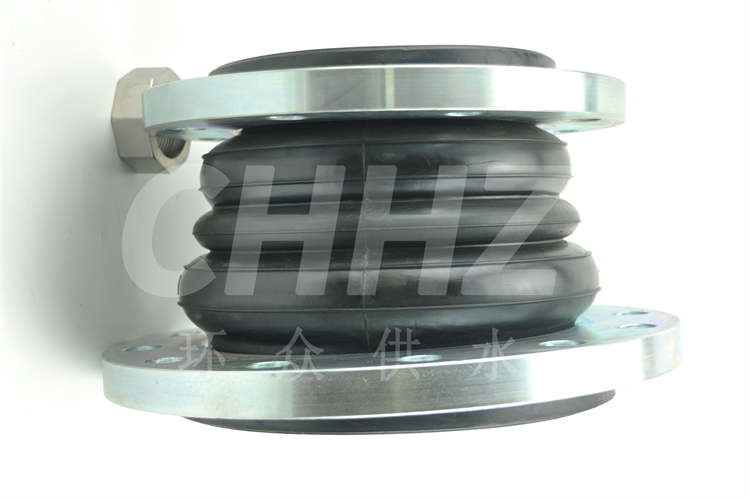

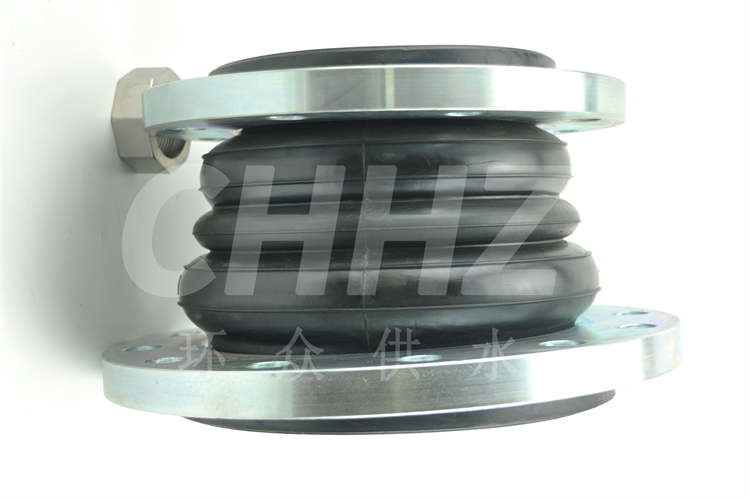

rubber joint wrapping

Rubber joint wrapping is a technique used to provide additional protection and reinforcement to rubber expansion joints in various industrial applications. These joints are designed to absorb movement, dampen vibration, and compensate for misalignment in piping systems. However, in certain environments, they may require extra safeguarding to prolong their lifespan and ensure optimal performance.

The wrapping process involves applying a protective layer around the rubber joint to shield it from harsh external conditions, abrasion, or potential damage. There are several methods and materials used for rubber joint wrapping, including the use of external sleeves, fabric wraps, or coatings.

One common approach to rubber joint wrapping is the use of external sleeves made of durable materials such as neoprene, EPDM, or other synthetic fabrics. These sleeves are designed to fit snugly around the rubber joint, forming a protective barrier against moisture, chemicals, and physical impact. The sleeves may also offer thermal insulation, further safeguarding the joint from extreme temperatures.

In some cases, rubber joints are wrapped with fabric materials that provide an additional layer of protection. This fabric wrapping can be impregnated with rubber or other elastomers to create a composite structure that enhances the joint's resistance to abrasion and wear.

Another method involves applying specialized coatings to the exterior of the rubber joint, such as polyurethane or epoxy-based formulations. These coatings create a durable, impermeable layer that shields the joint from corrosive substances, UV radiation, and mechanical stress.

Regardless of the specific wrapping method used, the goal is to enhance the resilience of the rubber joint, extending its service life and reducing the need for frequent maintenance or replacement. Properly wrapped rubber joints can withstand challenging operating conditions and contribute to the overall reliability and efficiency of industrial piping systems.

In conclusion, rubber joint wrapping plays a crucial role in safeguarding rubber expansion joints from environmental and operational hazards. Whether through the use of protective sleeves, fabric wraps, or specialized coatings, wrapping enhances the durability and integrity of rubber joints, ensuring their effective performance in demanding industrial environments.