The principle of rubber joints

The principle of rubber joints is to provide flexible connectivity between piping systems that can accommodate movement, absorb vibration, and compensate for misalignment. These components are crucial for various industrial applications where pipelines are subject to thermal expansion, contraction, or external forces.

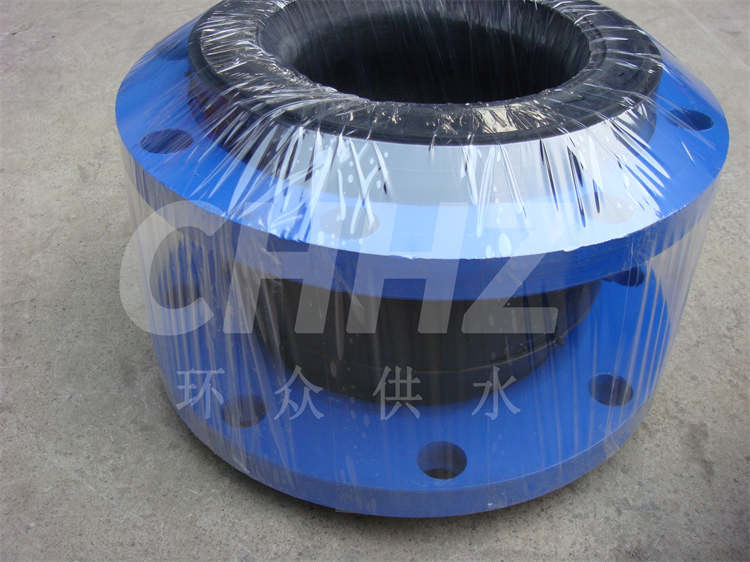

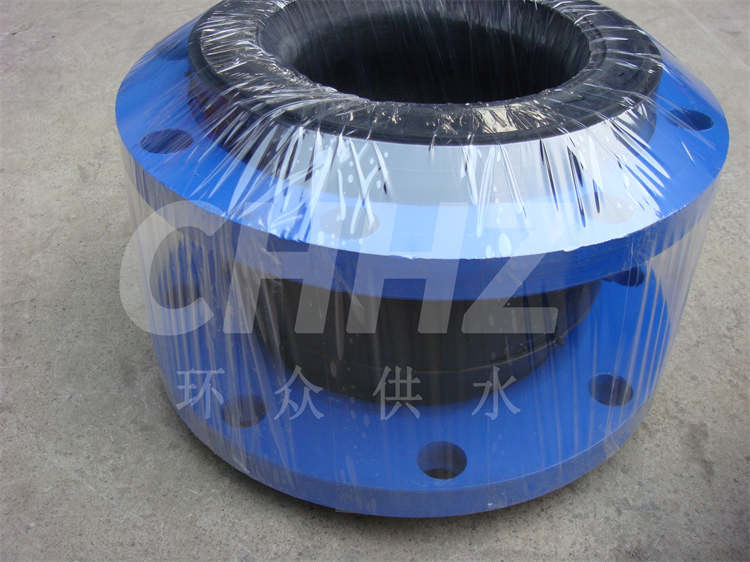

Rubber joints, also known as expansion joints or flexible connectors, consist of a rubber body and have embedded reinforcement materials such as synthetic fabrics or metal wire. The rubber body allows for movement and flexibility, while the reinforcement materials help maintain the structural integrity of the joint.

The primary function of a rubber joint is to absorb and isolate vibrations and shocks that occur within a piping system. This helps to prevent these disturbances from affecting other components or structures, thereby reducing the risk of damage or fatigue. Additionally, rubber joints can compensate for minor misalignments or axial movements, which is essential in situations where rigid connections may fail due to thermal expansion or settlement.

When the connected piping system experiences thermal expansion or contraction, the rubber joint flexes and deforms to accommodate the movement, effectively relieving stress on the system. This capability reduces the likelihood of leaks, cracks, or failures that can result from excessive mechanical strain.

In addition to their flexibility, rubber joints also provide a damping effect, absorbing energy from pulsating flows or pressure surges within the pipeline. This helps to minimize the transmission of pressure fluctuations and dynamic loads, thereby contributing to the overall stability and safety of the system.

The design and material composition of rubber joints play a critical role in their performance. Depending on the specific application and operating conditions, rubber joints can be constructed using different elastomers, such as natural rubber, neoprene, EPDM, or other synthetic compounds. These materials are selected based on their compatibility with the conveyed media, resistance to chemical exposure, and temperature range.

In conclusion, the principle of rubber joints revolves around their ability to provide flexible and resilient connections within piping systems. By accommodating movement, absorbing vibrations, and compensating for misalignment, rubber joints help to maintain the integrity and operational efficiency of industrial pipelines. Their design, material selection, and installation play a crucial role in ensuring reliable performance and longevity in diverse industrial environments.