Rubber Components in Waterproof Cable Joints: Ensuring Sealing and Protection

Introduction: Rubber components play a critical role in ensuring the effectiveness of waterproof cable joints. This article provides an overview of the significance and functionality of rubber parts within waterproof cable joints, highlighting their specific roles in providing sealing, protection, and longevity to cable connections in various applications.

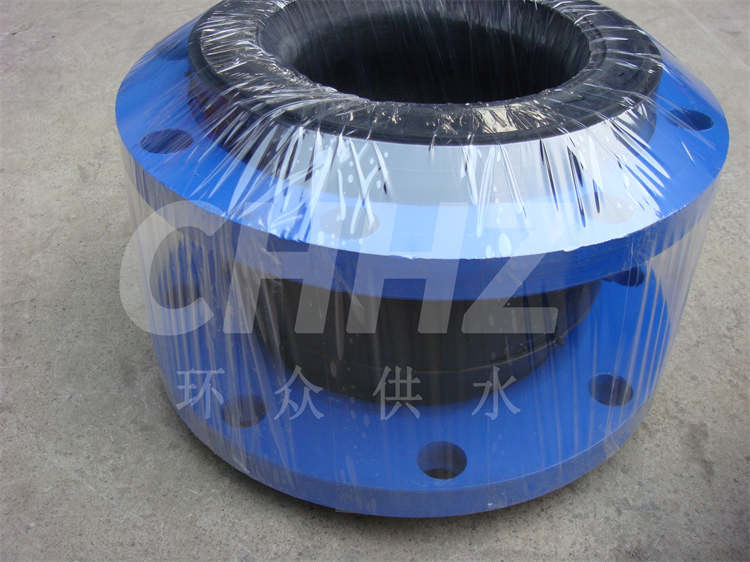

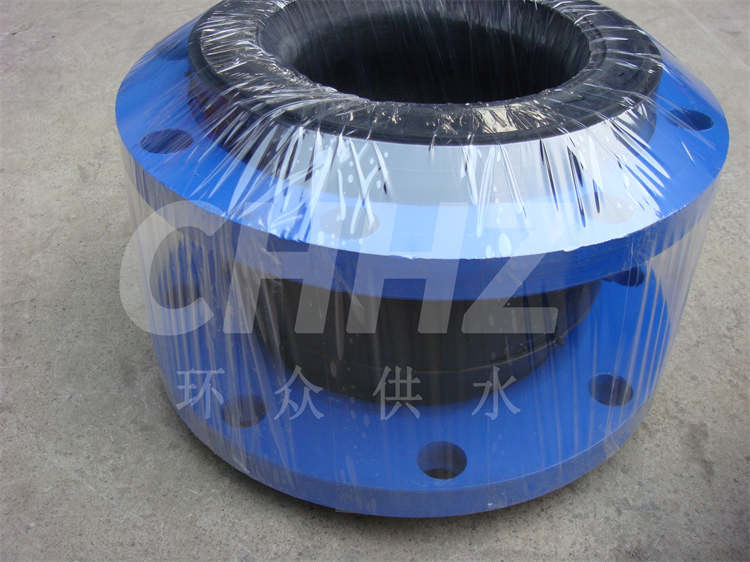

Sealing Function: Rubber components in waterproof cable joints are primarily responsible for providing a reliable seal against moisture, dust, and other environmental factors. The use of high-quality elastomeric compounds allows these rubber parts to create a tight seal around the cable connections, preventing the ingress of water and other contaminants. This is particularly vital in outdoor and underground applications, where cables are exposed to harsh environmental conditions.

Protection Against Mechanical Stress: In addition to sealing, rubber components within waterproof cable joints serve as a protective barrier against mechanical stress. They help to absorb and distribute mechanical forces, such as tension, compression, and vibration, that could potentially compromise the integrity of cable connections. By effectively cushioning and protecting the cables, these rubber components contribute to the overall durability and longevity of the joint.

Flexibility and Adaptability: Rubber parts are inherently flexible, allowing them to conform to the contours of cables and fittings within the joint. This flexibility ensures a snug fit and uniform compression, even in irregular or challenging geometries, thus enhancing the overall effectiveness of the sealing and protective functions. Moreover, the adaptability of rubber components enables them to accommodate cable movement and thermal expansion, maintaining a secure and reliable connection over time.

Resistance to Environmental Factors: Rubber materials used in waterproof cable joints exhibit excellent resistance to a wide range of environmental factors, including UV radiation, ozone exposure, and temperature fluctuations. This resistance ensures that the rubber components remain durable and functional in outdoor and exposed applications, extending the service life of the cable joint.

Applications: The application of rubber components in waterproof cable joints is widespread across various industries and sectors. These cable joints are commonly utilized in outdoor electrical installations, underground cabling for utilities, marine and offshore applications, and industrial environments where moisture and environmental challenges are prevalent. The sealing and protective properties of rubber components make them invaluable for maintaining the integrity and reliability of cable connections in these diverse settings.

Conclusion: Rubber components are indispensable elements in the design and construction of waterproof cable joints. Their crucial roles in providing sealing, protection against mechanical stress, flexibility, and resistance to environmental factors make them essential for ensuring the long-term performance and integrity of cable connections. As the demand for reliable and durable cable joints continues to grow across different industries, the significance of high-quality rubber components in waterproof cable joints remains paramount.