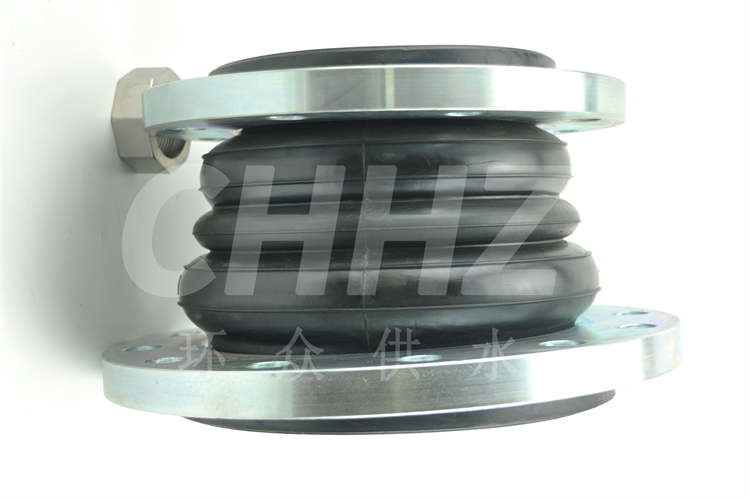

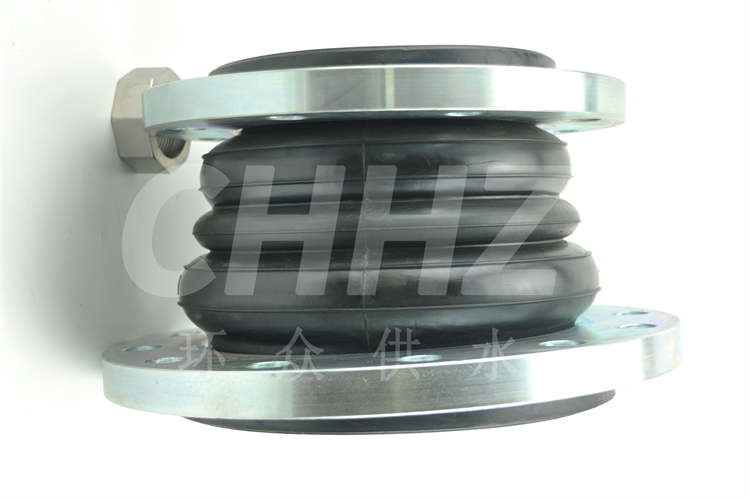

Installation Method of Rubber Hose Metal Joints

The installation of rubber hose metal joints is a critical process in various industrial applications, ensuring the proper functioning and integrity of fluid systems. This article provides a comprehensive guide on the installation method of rubber hose metal joints, outlining the necessary steps and best practices for a safe and effective installation process.

Preparation and Safety Measures: Before commencing the installation, it is essential to ensure that the work area is clear of obstructions and that appropriate safety measures are in place. Personal protective equipment such as gloves, eye protection, and suitable clothing should be worn to prevent injuries during the installation process. Additionally, ensure that the fluid system is depressurized and that all relevant safety protocols are followed.

Inspection of Components: Prior to installation, carefully inspect the rubber hose and metal joint components for any signs of damage, wear, or defects. Ensure that the metal joint threads are clean and free from any debris, and verify that the rubber hose is free from cuts, abrasions, or other forms of deterioration that could compromise its integrity.

Application of Lubricants: To facilitate the installation process, apply a suitable lubricant to the metal joint threads and the inner surface of the rubber hose. This will ease the assembly of components and minimize the risk of damage to the rubber hose during installation.

Aligning the Components: Position the metal joint and rubber hose in alignment with each other, ensuring that the threads engage smoothly. Carefully thread the metal joint onto the rubber hose by hand, avoiding cross-threading or applying excessive force, which could damage the components.

Tightening the Metal Joint: Using appropriate hand tools, such as wrenches or spanners, proceed to tighten the metal joint onto the rubber hose. Apply controlled force to achieve a secure connection, ensuring that the joint is tightened to the manufacturer's recommended torque specifications. Take care not to over-tighten, as this may damage the hose or the joint and compromise the integrity of the assembly.

Inspection and Testing: Upon completion of the installation, inspect the assembled joint for proper alignment, security, and integrity. Ensure that there are no leaks, and verify that the joint is properly seated and sealed. Conduct a pressure test, if applicable, to validate the integrity of the assembly and verify that it is ready for operation.

Documentation and Maintenance: Maintain comprehensive records of the installation, including details of torque specifications, inspection results, and any additional notes related to the assembly. Additionally, establish a regular maintenance schedule to inspect and maintain the rubber hose metal joint assemblies to ensure continued reliability and performance.

In conclusion, the installation of rubber hose metal joints demands meticulous attention to safety, proper procedures, and adherence to manufacturer guidelines to ensure the reliability and integrity of fluid systems in various industrial applications. Following the outlined steps and best practices will enable a safe and effective installation process, resulting in the optimal functioning of rubber hose metal joint assemblies.