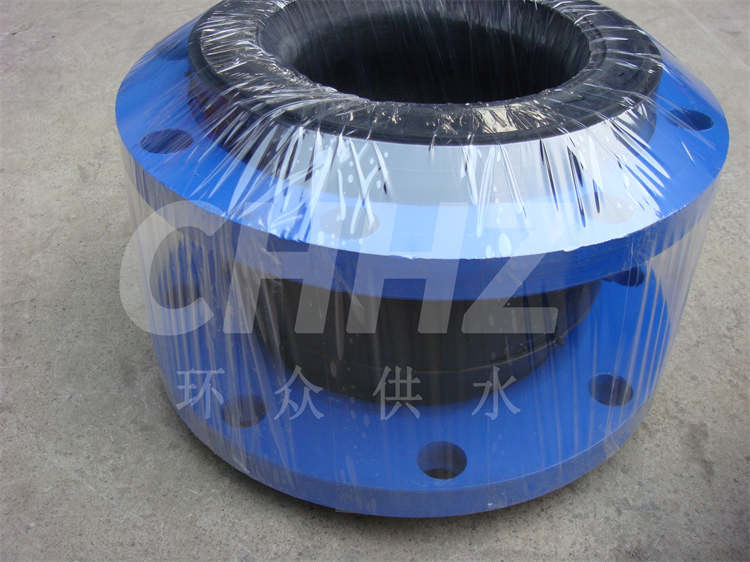

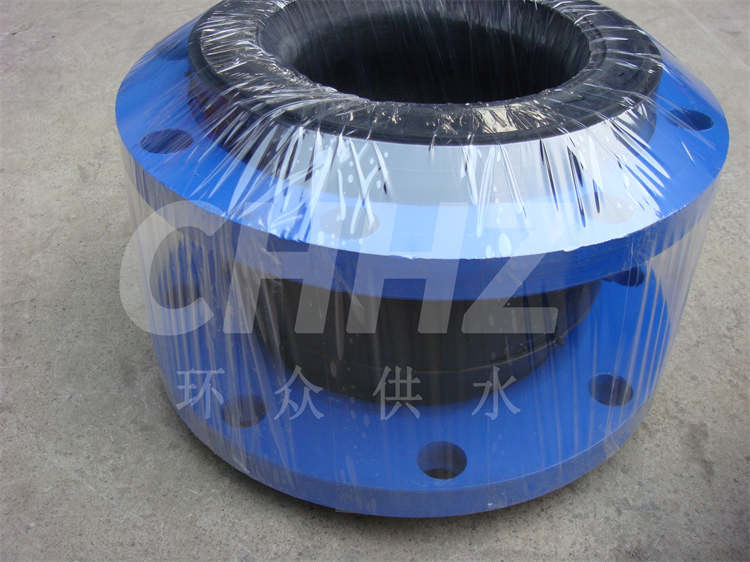

Flexible Rubber Joints for Mining Equipment

In the mining industry, the use of heavy equipment in various processes requires robust and reliable connections to ensure the efficient transfer of materials and fluids. Flexible rubber joints play a crucial role in handling the dynamic and demanding conditions encountered in mining operations. This article highlights the importance and benefits of flexible rubber joints for mining equipment.

Flexible rubber joints, also known as rubber expansion joints, are designed to absorb vibrations, reduce noise, and compensate for misalignments in piping systems. In the context of mining equipment, these joints serve multiple purposes, including:

Vibration Damping: The harsh operational environment in mining often leads to significant vibrations generated by equipment such as crushers, conveyors, and pumps. Flexible rubber joints effectively absorb these vibrations, preventing them from being transmitted to the piping system and surrounding structures, thus minimizing wear and tear on equipment and reducing the risk of structural damage.

Compensation for Movement and Misalignment: Mining equipment is subject to dynamic movements, thermal expansion and contraction, as well as potential misalignments due to ground shifts or regular maintenance activities. Flexible rubber joints have the ability to accommodate such movements and misalignments, thereby reducing stress on the piping and equipment, and extending their service life.

Noise Reduction: The operation of mining equipment can produce high levels of noise, which can have adverse effects on both worker safety and surrounding communities. Flexible rubber joints help in attenuating the transmission of noise through the piping, contributing to a quieter and more comfortable working environment.

Corrosion Resistance: In corrosive mining environments, such as those involving the handling of acidic or abrasive materials, flexible rubber joints offer superior resistance to corrosion and degradation compared to metallic alternatives. This resistance contributes to the longevity and reliability of the joints, even in aggressive operating conditions.

When selecting flexible rubber joints for mining equipment, it is essential to consider factors such as pressure ratings, temperature range, chemical compatibility, and the specific requirements of the application. Additionally, proper installation and maintenance practices are crucial to ensuring the optimal performance and longevity of the joints.

In conclusion, the use of flexible rubber joints in mining equipment brings substantial benefits in terms of vibration damping, movement compensation, noise reduction, and corrosion resistance. These advantages contribute to improved equipment reliability, reduced maintenance costs, and enhanced safety in mining operations. Therefore, the selection and application of high-quality flexible rubber joints are vital considerations for optimizing the performance and longevity of mining equipment.