Requirements for Rubber Hose Couplings Used in Coal Mines

When it comes to coal mining operations, the safety, reliability, and efficiency of equipment and components are of utmost importance. Rubber hose couplings play a crucial role in fluid transfer and ventilation systems within coal mines, and as such, certain requirements must be met to ensure their effectiveness and compliance with industry standards. In this article, we will outline the key requirements for rubber hose couplings used in coal mines to ensure safe and reliable performance in this demanding environment.

First and foremost, rubber hose couplings intended for use in coal mines must be constructed from materials that are compatible with the conditions prevalent in these environments. They need to exhibit exceptional resistance to abrasion, corrosion, and exposure to coal dust and other particulate matter commonly found in mining operations. Additionally, the materials must be non-combustible and capable of withstanding elevated temperatures to ensure the safety of the equipment and personnel in the event of a fire or thermal exposure.

Furthermore, the design and construction of rubber hose couplings for coal mines must incorporate features that prevent the build-up of static electricity. Given the presence of combustible gases and dust in mining environments, the couplings must be antistatic or conductive to mitigate the risk of static discharge, which could potentially lead to hazardous situations such as fires or explosions.

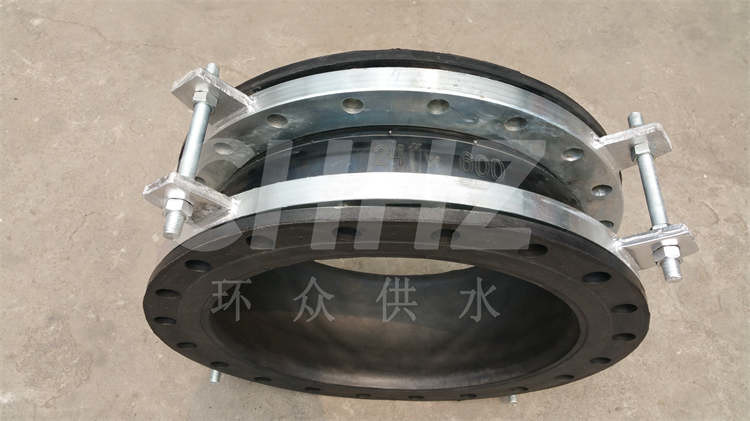

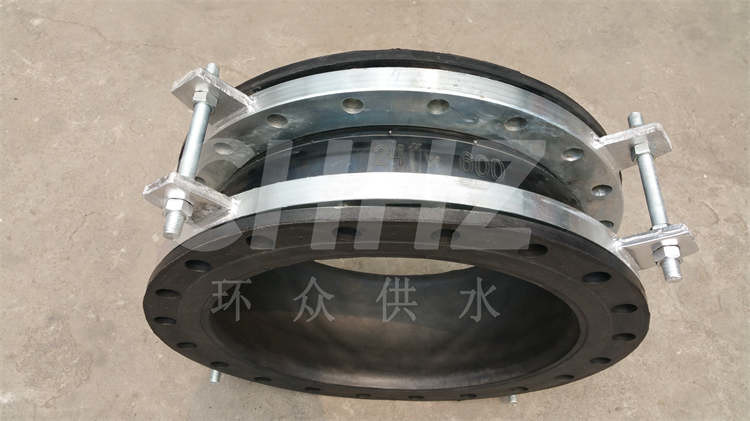

In line with safety considerations, the installation and secure attachment of rubber hose couplings in coal mining applications are critical. Couplings must be designed to provide a reliable and leak-free connection, even under the high pressures and dynamic movement often encountered in mining operations. Additionally, quick and efficient assembly and disassembly of couplings are essential to minimize downtime during maintenance and replacement activities.

Moreover, considering the demanding nature of coal mining operations, rubber hose couplings must demonstrate resilience and durability. They should be capable of withstanding the mechanical stresses and impacts that can occur in the harsh and rugged conditions found in mining environments. The couplings must also resist degradation from exposure to oils, lubricants, and chemicals commonly used in mining machinery and processes.

Another critical requirement for rubber hose couplings in coal mines is their compliance with industry regulations and standards. These may include specific guidelines for materials, construction, performance, and safety certifications to ensure that the couplings meet the stringent requirements set forth by regulatory bodies and industry organizations.

In conclusion, the requirements for rubber hose couplings used in coal mines are driven by the need for safety, reliability, and robust performance in challenging operating environments. From materials and design to installation and safety considerations, these requirements are crucial for ensuring that the couplings effectively support the fluid transfer and ventilation systems critical to coal mining operations. By meeting these requirements, manufacturers and suppliers can provide coal mines with the assurance that their rubber hose couplings are engineered to deliver reliable and safe performance in the demanding conditions of the mining industry.