The lifespan of rubber flexible joints and concrete

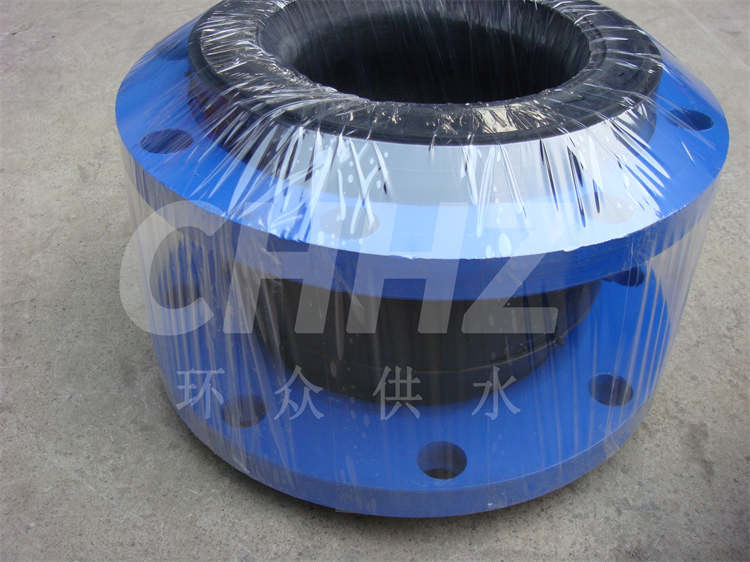

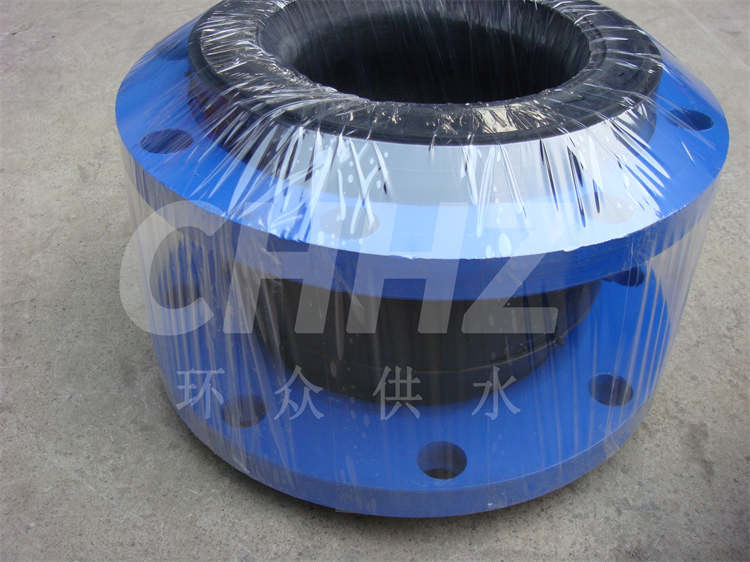

The lifespan of rubber flexible joints and concrete can have a significant impact on the performance and longevity of infrastructure across various applications. Rubber flexible joints are commonly used in piping systems to absorb vibration, accommodate movement, and reduce noise, while concrete is widely employed in construction for its strength and durability. Understanding the lifespan and performance characteristics of these materials is vital for ensuring the reliability and efficiency of structures and systems.

Rubber flexible joints, when properly designed, installed, and maintained, can have a relatively long service life. The lifespan of a rubber flexible joint is influenced by factors such as the quality of the rubber material, environmental conditions, mechanical forces, and exposure to chemicals. High-quality rubber compounds with resistance to abrasion, aging, and weathering can extend the service life of flexible joints, especially in demanding industrial or infrastructure settings. Proper installation and maintenance practices, including regular inspection and replacement of worn components, can also contribute to prolonging the usable lifespan of rubber flexible joints.

In the case of concrete, its lifespan and performance are dependent on various factors, including the quality of materials, design considerations, construction practices, and environmental exposure. Well-designed and properly cured concrete structures can maintain their integrity for decades, especially when exposed to moderate usage and environmental conditions. Factors that can affect the lifespan of concrete structures include exposure to harsh chemicals, freeze-thaw cycles, heavy loads, and environmental pollutants. Adequate maintenance, timely repairs, and protective coatings can help prolong the lifespan of concrete structures, ensuring their continued functionality and structural integrity.

When rubber flexible joints are used in conjunction with concrete structures, their lifespans are interconnected. In applications such as bridge construction, industrial facilities, or wastewater treatment plants, where concrete structures are subjected to movement, vibration, or thermal expansion, the inclusion of rubber flexible joints can help mitigate stress on the concrete components. By absorbing movement and reducing the transmission of forces, rubber flexible joints can contribute to the preservation of concrete structures, potentially extending their service life.

In conclusion, understanding the lifespan and performance characteristics of rubber flexible joints and concrete is essential for the successful long-term operation of infrastructure and systems. Proper material selection, installation, and maintenance practices are crucial for maximizing the lifespan of rubber flexible joints and concrete structures, ensuring the reliability and functionality of the overall infrastructure. By addressing these considerations, engineers and infrastructure managers can make informed decisions to enhance the performance and durability of structures and systems.