The use environment of high pressure resistant rubber joints.

Rubber joints have been used as flexible pipeline connectors, which need to withstand as much pressure as metal pipes, so the selection of materials for joints as rubber products is very critical, and the use of different gums is different. Depending on the use of different environments such as like: seawater, acid and alkali media, high temperature media, low temperature media, granular media, chemical media, etc., different rubber materials need to be used to overcome. The high-pressure rubber joint we are talking about today is a kind of pipeline joint with high elasticity, high airtightness, medium resistance and weather resistance.

The natural rubber has good elasticity and expansion performance, which can provide sufficient and effective compensation for the displacement caused by multiple environmental influences during the operation of the pipeline. Polyester cord fabric as the main material of the rubber joint can effectively improve the pressure resistance of the product, avoiding the bursting or pulling off of the sphere during the operation caused by excessive pressure. There are two types of high pressure rubber joints: loose flange high pressure rubber joints and fixed flange high pressure rubber joints.

Loose flange high pressure rubber joint is composed of rubber body and two pieces of live flange. The rubber body is made of inner and outer synthetic rubber, skeleton nylon cord fabric and pressurized steel ring, which is vulcanized at high temperature by advanced air-blowing process. The rubber joint produced in this way can increase the pressure of the joint, which is 5 times higher than the common rubber joint. Especially, it can show its special efficacy in the pipeline of corrosion resistance, acid and alkali resistance and oil resistance, and improve the service life of rubber joints.

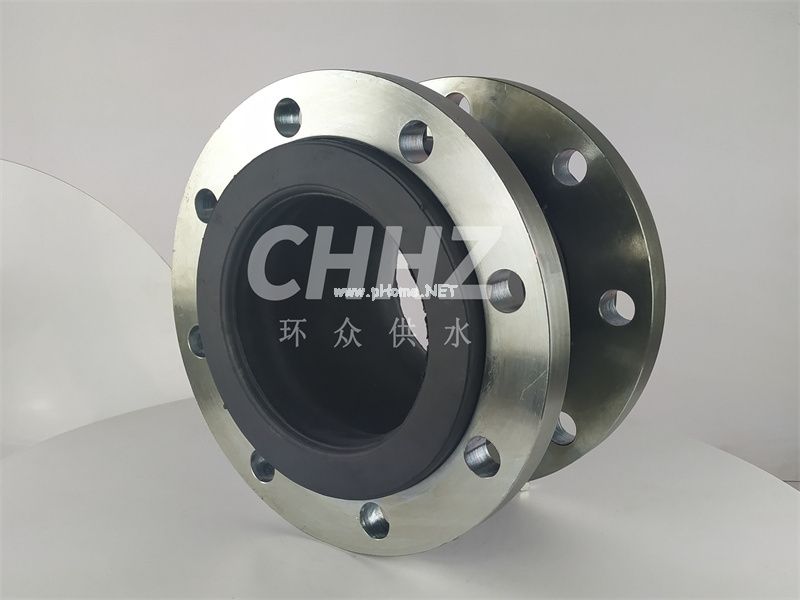

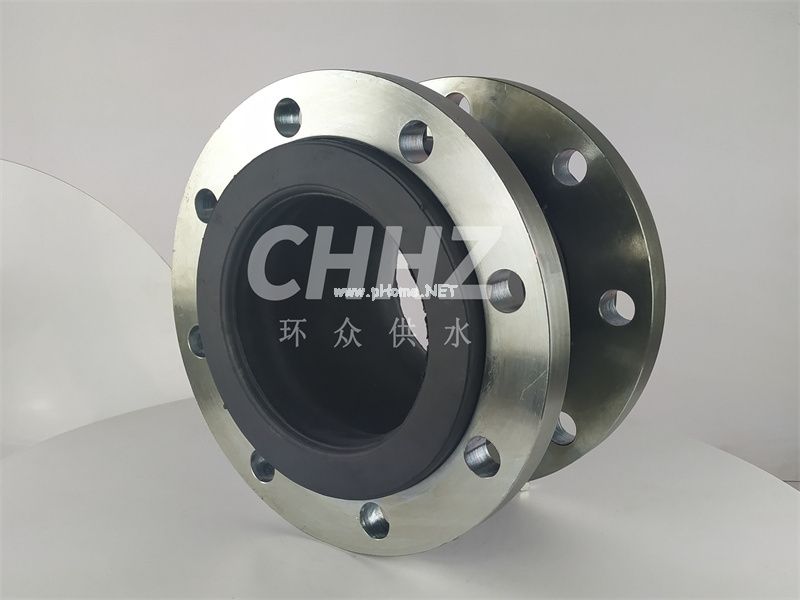

Fixed flange high pressure rubber joint is made of rubber body and two flanges through a special process, the same is made by air blowing mold process and high temperature vulcanization, which has a super strong anti-latto effect. If it is used in the place where the pump and valve outlets are connected to the pipeline or in the pipeline with foundation settlement, it can show its unique function of preventing pull-off and effectively prolong the service life of rubber joints, which brings unexpected benefits to users.