Notes on rubber expansion joints

Notes on rubber expansion joints

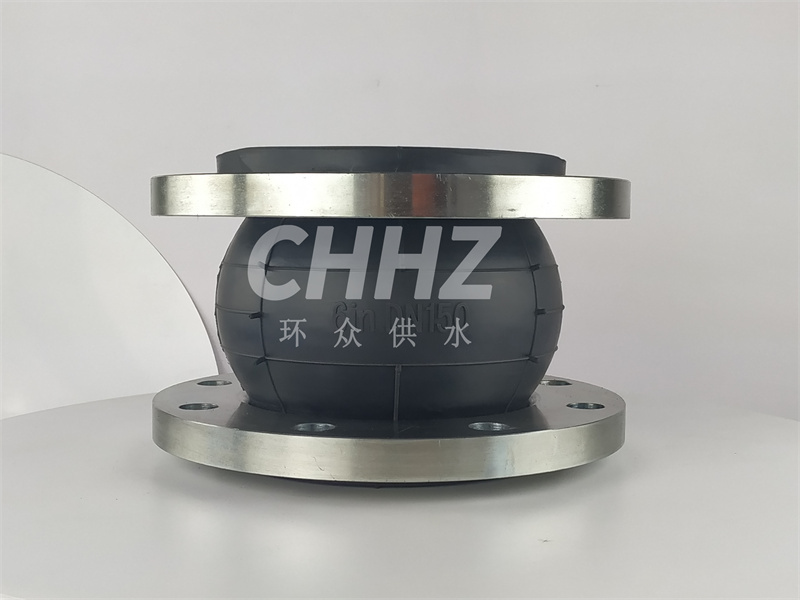

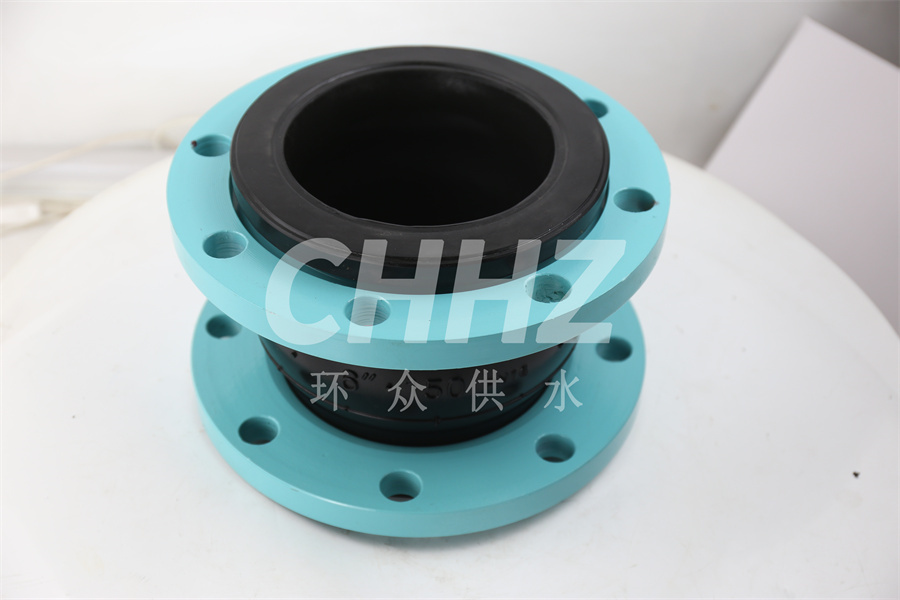

Rubber expansion joint is a new type of pipeline connection, which can compensate for the expansion and contraction of the pipeline, regulate the expansion and contraction, and protect the normal work of the pipeline. Soft joints are commonly used in the inlet and outlet of water pumps. In normal use, water pumps are generally used to lift and convey liquids or to pressurize liquids, that is, the mechanical energy of the prime mover is converted into liquid energy, so as to realize the liquid pumping machines collectively called pumps.

When you choose rubber expansion joint, you can save the process of rust removal and corrosion prevention, the product is neat and beautiful. After the pipeline is installed with circulating pump rubber soft joint, it can not only solve the installation problems caused by different centers of the pipeline, but also compensate the expansion phenomenon caused by thermal stress of the pipeline, and the mechanical vibration generated by the operation of the pipeline can also be effectively controlled. Circulating pump rubber joint installed in the pipeline DN150 under the circulating pump rubber flexible joint its elongation and compression changes are based on the size of the nominal diameter of the product to determine the increase in compensation is obvious, but after DN200 its various displacements have changed.

But the rubber flexible expansion joint does have a difference, its axial compensation with the size of the nominal diameter is changing at this stage, the elongation and compression of each small range of rubber joints is basically the same, but from the overall trend, the expansion is growing steadily rubber flexible joints in the middle will use a combination of quality nylon cord fabric and hard steel wire as the skeleton layer of the rubber connection, strong and weak with good assurance.

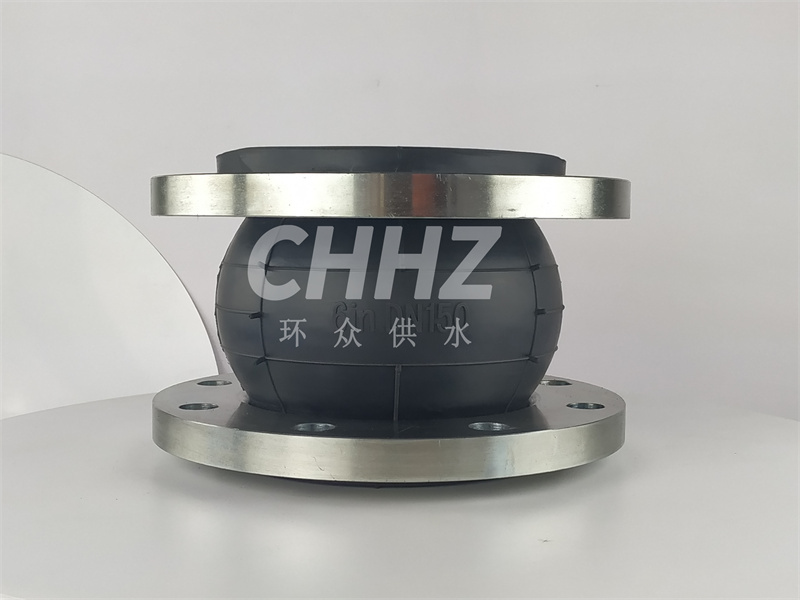

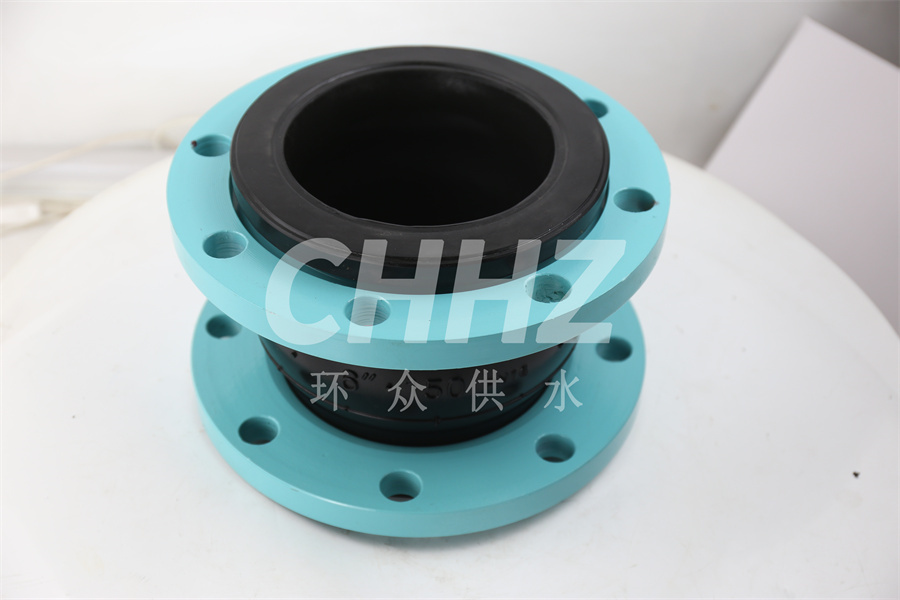

Reasons for damage to rubber flexible joints, rubber flexible expansion joints after a period of use, due to internal wear and corrosion, the overall joint pressure resistance decreases, the medium and stainless steel wire contact, in this case, chloride ions will cause serious corrosion of stainless steel, corrosion so that the outer stainless steel winding layer weakened, after the pipeline pressure reaches a certain level, leakage accidents will occur. External rubber soft joint, by anti-twisting, is metal winding stainless steel protruding burrs. Not only does the personnel leave a large residue when repairing, but in serious cases the surface layer of metal will break and the whole hose will fracture.

When connected mechanically with rubber joints, the joint strength can only reach 40 to 50 percent of the strength of the band body, cold glue way better quality, the bond strength can reach 60 to 70 percent, and hot glue hot glue joint, glue joint way to ensure the correct method of gluing.