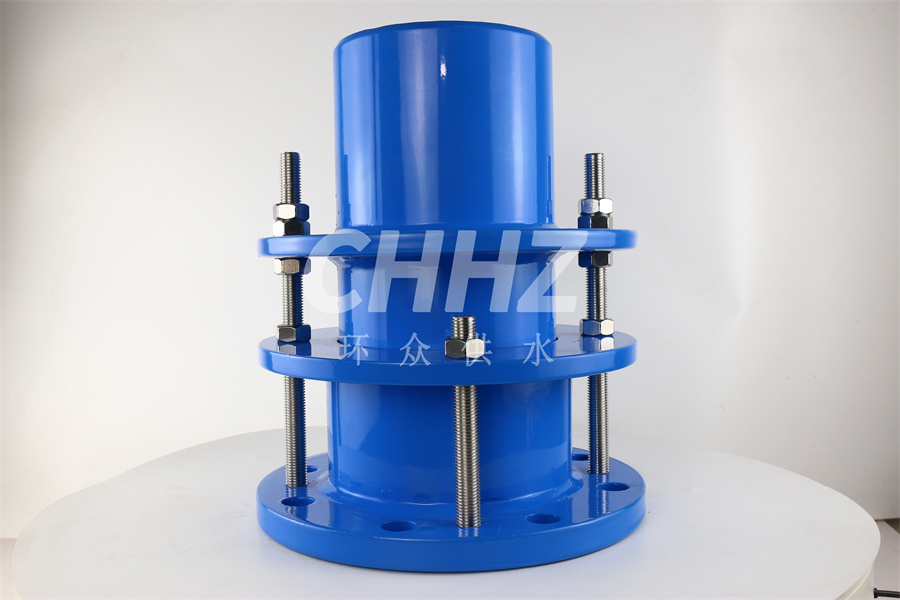

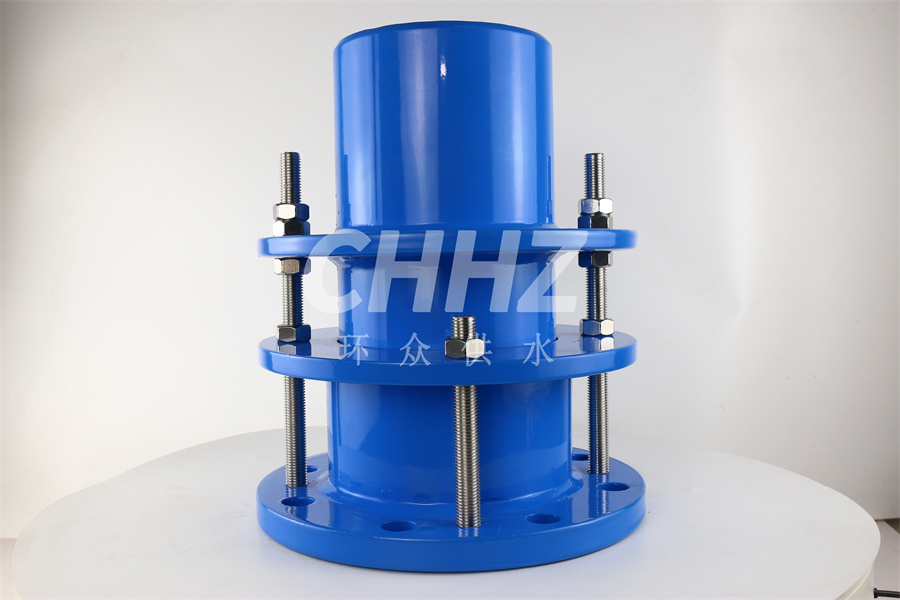

Installation of single flange limit expansion joint

Single flange limit expansion joint is composed of loose-fitting expansion joint and limit short pipe. It can prevent the leakage or damage of the compensation joint due to excessive displacement of the pipeline. It is mainly used for loose-fitting connection of pipelines that absorb axial displacement and bear pressure thrust within the allowable displacement range. The range can be free to expand and contract, lock the expansion amount to ensure the operation of the pipeline.

A lifting wrench can be used to open the single flange limit expansion joint several times to flush away the dirt; sealing surface damage. According to the degree of damage, it should be ground or ground after turning; the expansion rod is bent, tilted or the lever and pivot point are skewed, which makes the single flange limit expansion joint misaligned. It should be reassembled or replaced; the elasticity of the sealing rubber ring is reduced or lost. Measures such as replacing the sealing rubber ring and readjusting the opening pressure should be taken.

Brief description of installation of single flange limit expansion joint1)Clean the inner cavity of the packing and check whether the surface is scratched and burred.

2)Check the radial circular runout of the single flange limit expansion joint in the sealing part with a percentage table, and its tolerance should be within the allowed range.

3)The cavity of the single flange limit expansion joint should be coated with filler or lubricant suitable for the medium.

4)For the packing packed in rolls, a stick of the same size as the shaft diameter should be taken and wound on top of the single flange limit expansion joint before cutting it off with a knife, the cut can be flat but into a 45° bevel.

5)Filler should be filled one by one, not several at a time. When the number of packing roots is 4 to 8, the filling should make the interfaces stagger 90° from each other; two fillers stagger 180°; 3 to 6 stagger 120° to prevent leakage through the single flange limit expansion joint.

6) After one is filled, the gland should be pressed, but the pressure should not be too high. At the same time, rotate the spindle so that the assembled compression force tends to be parabolic in distribution. Then loosen the gland slightly, and the single flange limit expansion joint filling is considered complete.

7) Conduct a running test to check whether the sealing requirements are met and to verify the degree of heat generation. If it cannot be sealed, the packing can be pressed tightly; if the heat generation is too great, loosen the single flange limit expansion joint a bit.

8) The leakage should be checked frequently, and if the leakage is found to exceed the allowed value, it should be pressed and adjusted in time.

9) The wear, bending and eccentricity of the shaft single flange limit expansion joint are the main causes of leakage. The use of bearings should be checked regularly and the packing should be installed not far from the bearings as far as possible. The permissible radial circular runout of the single flange limit expansion joint is below.

10) soft and hard different packing will have good effect when used, but the hard packing should be in the deep part when loaded, and the soft packing should be near the gland

11) The packing should be renewed regularly. Care should be taken not to scratch the inner wall and surface of the single flange limit expansion joint when disassembling and assembling.

12) When the packing does not match the size of the packing cavity, it is strictly forbidden to knock the single flange limit expansion joint flat with a hammer.