The selection criteria of rubber soft joints indicate and quality assurance requirements

In the current industrial production market, the requirements of rubber joints have been steadily rising, although nowadays industrial production is not as rapid as before, and even the development trend of lowering, but for rubber joints of this kind of machine and equipment components, or in making sure that the requirements, not only is not endangered by industrial development, and still in the process of improving. This is also a spectacular industrial production.

The selection criteria of rubber flexible joints and the development of appropriate selection and design programs according to the specific use of rubber hose joints should generally take into account the following matters: 1. The application criteria of rubber joints: (1) the standard of pressure and operating conditions; (2) the type of material at work and the working temperature; (3) the indoor environmental conditions at work and the working temperature. 2. The assembly position of rubber flexible joints, the corresponding connection 3. the specification type and less bending radius of rubber connectors; 4. the structure form and raw materials of rubber flexible joints; 5. the difficulty level of equipment maintenance and disassembly and replacement of pipes; 6. the provisions on the level of trustworthiness of plastic hoses and connectors; 7. the reliability and rationality of production and manufacturing process technology.

According to the above provisions, it is possible to clarify the basic premise of the structural form of the rubber hose joint, the type of material, the way of connection and sealing, and the way of production and manufacturing of its connectors and the way of assembly process of the total process of the plastic hose. It can be said that the adoption of rubber connectors, not only need to look at the pipeline construction, but also need to look at the material, natural environmental causes, etc. It can be said that many times in the selection of the type of rubber flexible joints, the level to be fully considered is not as simple as imagined, subject to each process needs to be considered.

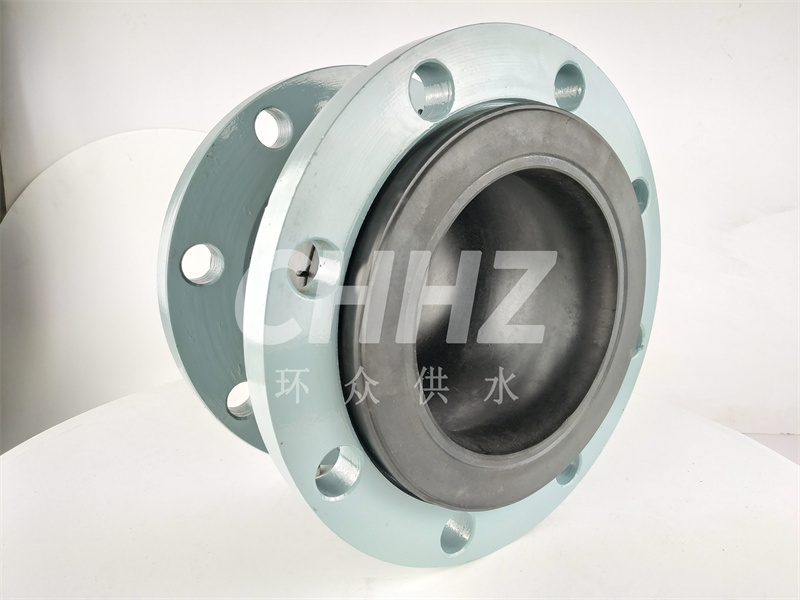

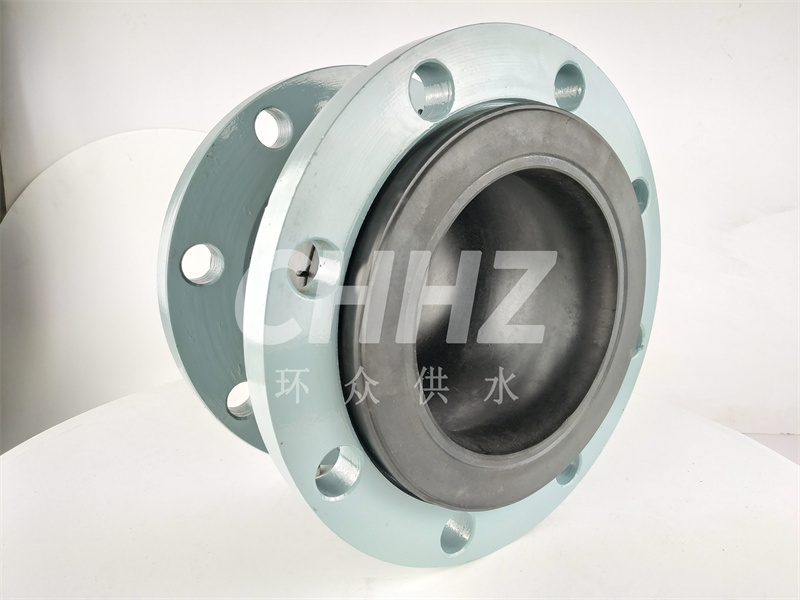

Rubber soft joints are used as soft joints in the middle of valve fittings and pipeline connections, which can have very good shock and noise reduction and compensation effects. Among the key raw materials of rubber soft joints are PP and PE. among them, PP material manufacturing rubber soft joints in the forming because of various external elements will cause the shrinkage of goods caused by the problem, if the production and manufacturing of the choice of suitable refrigeration temperature and post-treatment can reduce the shrinkage of goods after forming.

Plastic mold; multi-inlet mold shell to adjust the rate of filling each inlet, is symmetrical opening gate. The important parts of the mold should be reasonably set up with cooling circulation waterways to ensure that the cooling of the mold is very effective in clearing or reducing shrinkage. All molds should be free of burrs and have locking mold tightness, able to bear high pressure, fast and low viscosity wear-resistant material filling. Injection molding equipment; not enough feeding, injection molding machine screw or plunger pump damage is more serious, injection and test pressure melt material to produce leakage flow, reducing the working pressure of mold filling and material volume, resulting in wear-resistant material is not enough. The nozzle hole is very large or too small. Too small is very easy to block into the material safety channel, very large will make the injection force is small, filling the mold occurs difficult.

In the industrial chain pipeline, the quality and quality of rubber immediately jeopardizes the long-term application of rubber soft joints in the pipeline. The slight gap in the surface layer of the rubber joint will slowly rupture and expand. Within a short period of time, the rubber is substantially oxidized.

From the perspective of the analysis, it seems that most of the common failures of the goods are mainly due to the following elements: in the working pressure product test, the goods will be invalid because of unreasonable application or unscientific application settings. This stipulates that we take into account the size of the pressure and the level of load that can be borne in the design process. Secondly, because the harm of environmental factors is also the key element that causes the common failure of the commodity, thus we must enhance its anti-corrosion effect. In order to ensure safe application, we should be responsible for improving its reliability and increasing its safety factor.