Sleeve compensator, corrugated compensator assembly should meet the following requirements.

Sleeve compensator should maintain the same surface with the pipeline, not skewed.

The guide bracket assembled on the pipeline of the sleeve compensator should ensure that the pipeline compensator operates in a random expansion type and must not be deflected from the core.

The assembly length and temperature shift should be left out of the remaining collection capacity as explicitly stipulated in the design documents, and the remaining collection capacity should be measured when the design scheme documents are not required.

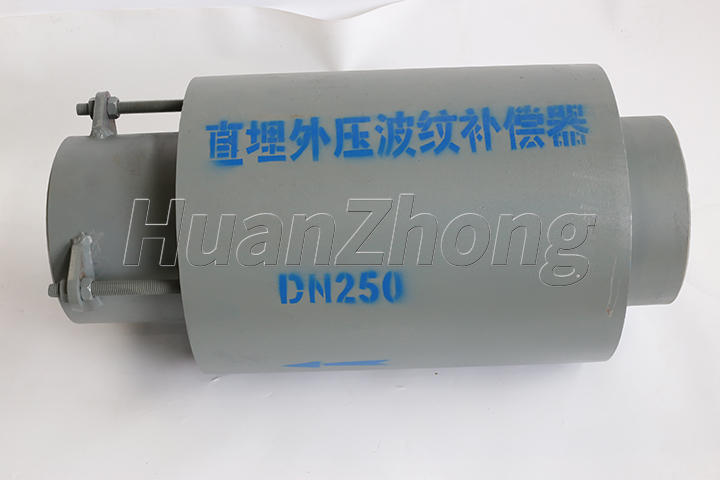

Corrugated compensator assembly requires special attention to the technical issues.

When assembling the corrugated compensator need to set a temporary fixed immobility, after the construction of the pipeline, that is, the temporary positioning device can be removed.

Corrugated compensator pre-lashings issue than the square compensator seems to be vital and should not be ignored. When purchasing the pipeline compensator from the manufacturer, the material ambient temperature of the heating pipeline network, the main parameters of the working pressure, the main parameters of the possible working temperature at the time of assembly and the construction plan of the pipeline compensator should be given to the manufacturer, so that the manufacturer can grasp the required pipeline compensator should have the ability to make up for the work, or immediately make clear to the manufacturer the provisions of the compensation working ability.

The pipes before and after the corrugated compensator should be on the same central axis.