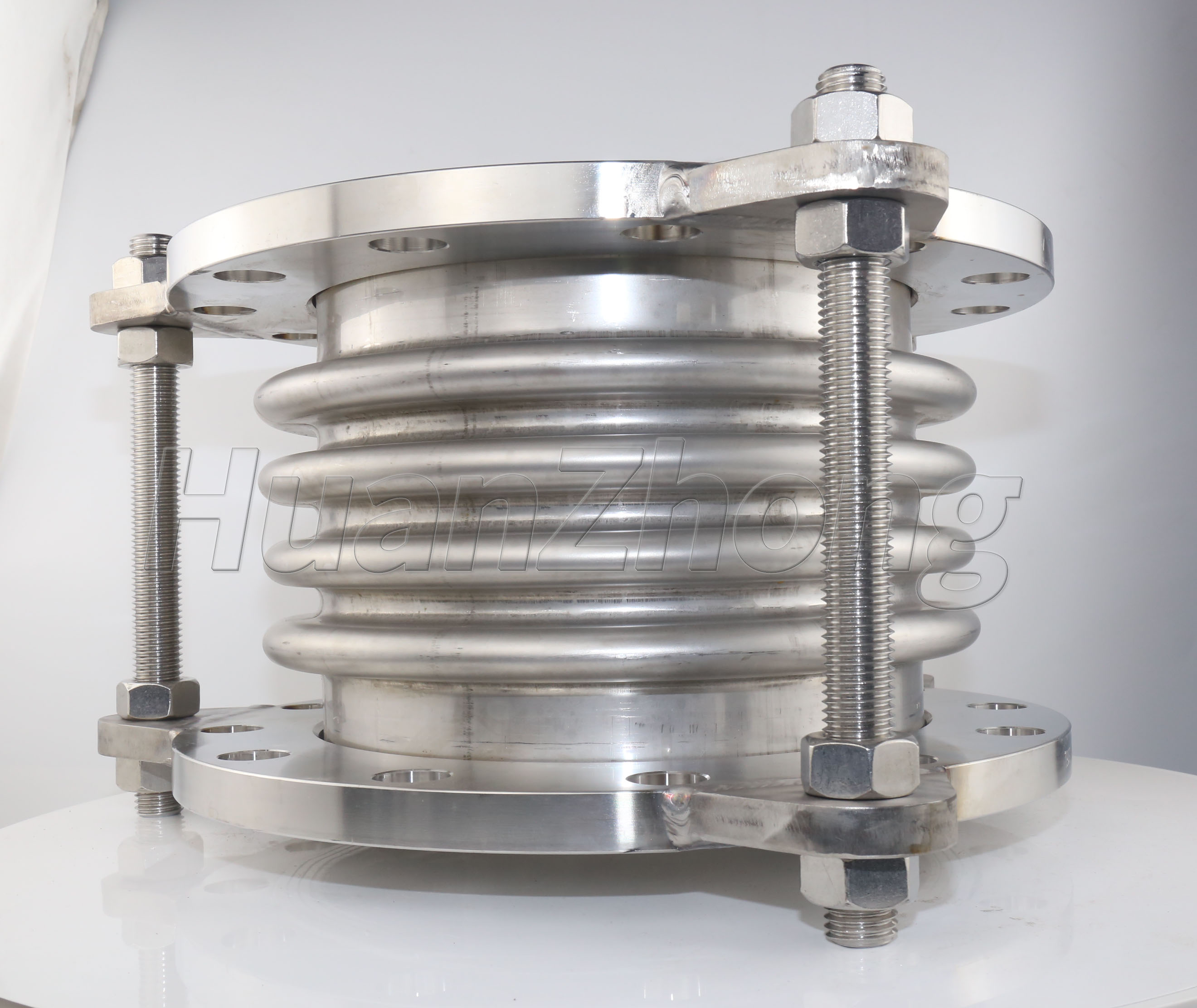

The procedural flow, process and manner of corrugated compensator assembly is shown below.

First measure the total length of the prepared corrugated compensator, draw the positioning for the pipeline compensator assembly on the pipeline, draw the compensator border line according to the length of the pipeline compensator.

Cut the pipeline according to the line, when the flange even and head to take into account the length occupied by the flange and gasket.

The pipeline compensator of coupling welding socket: use temporary seismic bracket to lift the pipeline compensator to carry out professional counterpart, the socket of both sides of the pipeline compensator should be and good, while carrying out welding, check the pipeline compensator parts suitable, the order of welding welding.

Joint flange socket pipe compensator: first two flange gasket temporary assembly in the pipe compensator, with temporary support, bracket will pipe compensator support tied up, carry out professional alignment, while carrying out welding, check the pipe compensator parts suitable, remove the flange foot bolt, remove the pipe compensator, the two flanges to carry out welding, welding on the clearance of welding scars, check the welding welding quality, up to standard After then carry out anti-rust solution to the inside and outside welding seam, the pipe compensator will be extended to carry out the flange announcement assembly.