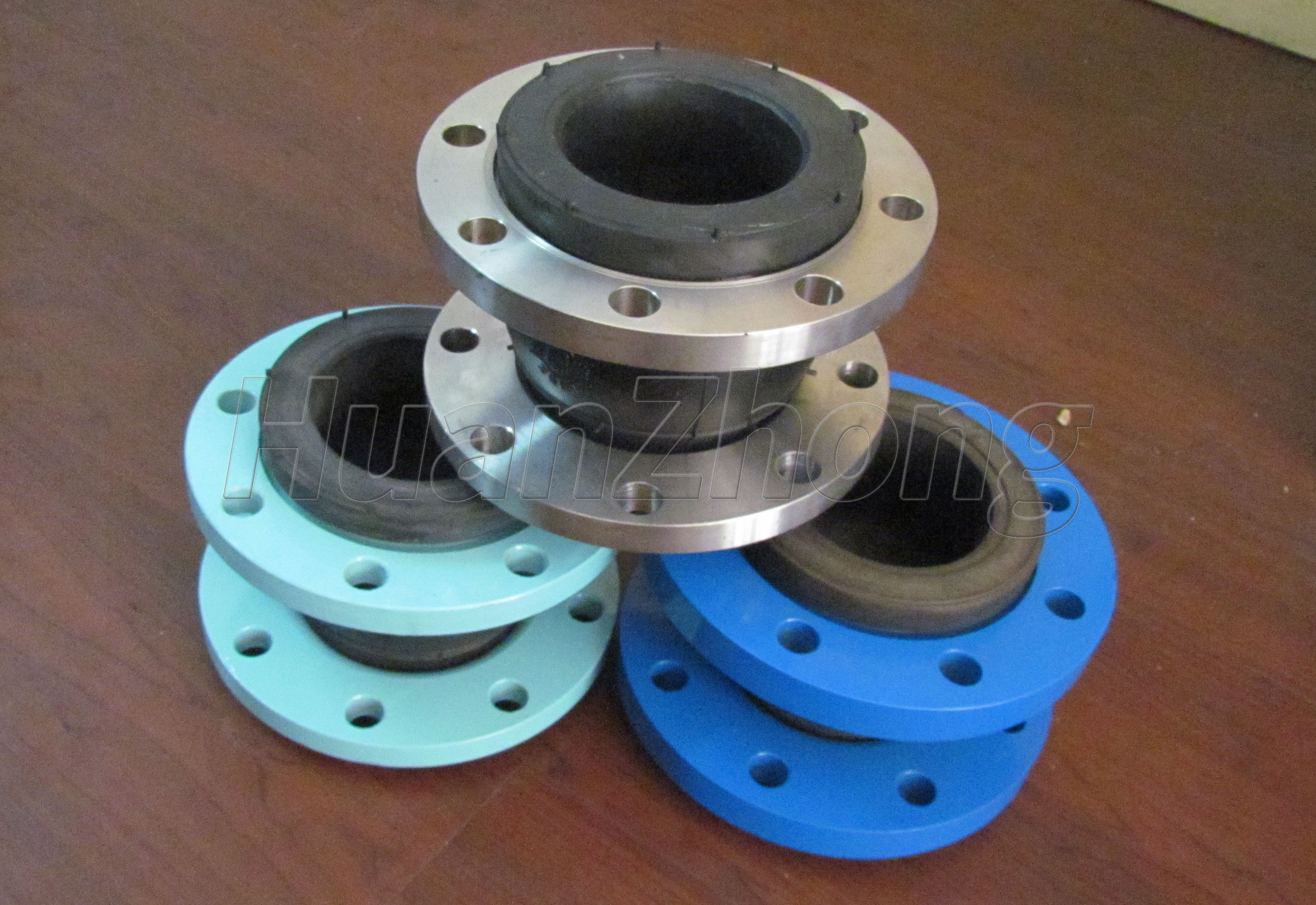

Flexible rubber joint flange anti-corrosion coating use process

Flexible rubber joint flange anti-corrosion coating construction of the basic requirements of the big have rubber joint products mainly using carbon steel flange connection. Flexible rubber joints in the use of the process for the flange corrosion prevention mainly using paint anti-corrosion. Anti-corrosion coatings, generally divided into conventional anti-corrosion coatings and heavy anti-corrosion coatings, is an essential coating in paint coatings. Conventional anti-corrosion coatings are in general conditions, such as metal to play the role of anti-corrosion, to protect the life of non-ferrous metal use; heavy anti-corrosion coatings are relative to conventional anti-corrosion coatings, can be applied in a relatively harsh corrosive environment, and has a class of anti-corrosion coatings that can achieve a longer protection period than conventional anti-corrosion coatings.

Flexible rubber joint flange corrosion protection coating construction of the basic requirements.

1 . Good adhesion and physical and mechanical properties: strong adhesion to the steel substrate or other coated materials, is the prerequisite for heavy anti-corrosion coating, especially the wet film adhesion, and has a low shrinkage rate, appropriate hardness, toughness, wear resistance, temperature resistance, etc.

2 . Good corrosion resistance: including resistance to chemical atmosphere, water, acid, alkali, salt, other solvents and other corrosion.

3 . Good resistance to media permeability: the excellent shielding effect of heavy anti-corrosion coatings requires that the coating has the lowest possible permeability to water and oxygen and other corrosion factors after film formation.

4 . Good construction performance: the coating reaches the appropriate thickness.