Metal compensator is generally used in what place?

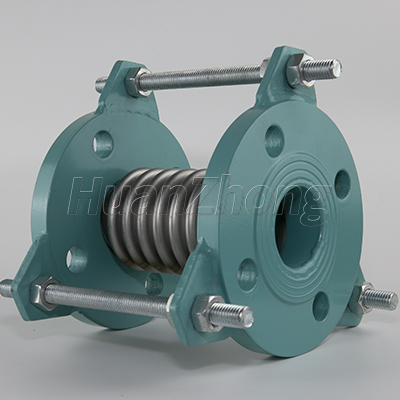

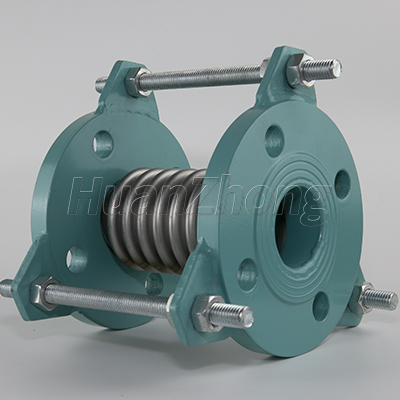

Metal compensator and non-metallic compensator, both belong to the compensator series, the common features of both: one is able to compensate the pipeline system, because of vibration or temperature generated by the expansion and contraction, so as to play the purpose of protecting the pipeline or valve, the second is also able to resist temperature, pressure, wear and tear, the third is easy to install and use, maintenance is also convenient, save time and effort. Metal compensator is a very important model in the compensator model, in-depth understanding of metal compensator is beneficial to our better selection, expressing the greater characteristics and benefits of metal compensator.

Can be applied to the solid but not flashy, gutter barricade of the pipeline, can also be applied to the direct burial paving with supplement, at this time the metal compensator at the appropriate inspection well or dark room. Metal compensator in the installation of the time and other corrugated compensator is not equivalent to it, the answer is the same. Metal compensator in the fixed bracket spacing provisions and fixed seat thrust calculations and ordinary corrugated compensator exactly the same. In order to make the project more safe and reliable, this corrugated compensator in addition to the requirement of close to the fixed bracket device, still require each fixed bracket spacing set up three guide bracket. The important lift metal compensator is used for pipeline axial filling, filling the shortage of large amount, so can simplify the planning of the pipeline guide bracket, so that the guide bracket spacing installation can be arbitrary debugging of these characteristics, then we can express the intention of this compensator in the time of selecting and setting the metal compensator.