How to choose a good rubber expansion joint?

There are many kinds of rubber joints and many working environments for application. Different rubber expansion joints are selected according to different requirements and environments. So the service life of rubber expansion joints depends not only on the quality, but also on the correct use and maintenance. If it cannot be used and maintained correctly, it will also seriously affect its quality and service life, and may even cause serious accidents, thus causing property damage. Rubber expansion joints usually use rubber, nylon and PTFE as the seat sealing materials, so the use temperature is subject to the seat sealing materials. The cut-off action is accomplished by pressing the plastic rubber joints (floating rubber joints) against each other by the metal spheres under the action of the medium. Rubber joint seal under a specific contact pressure, some areas will undergo elastic-plastic deformation. This deformation compensates for the manufacturing accuracy and surface roughness of the spheres and ensures the sealing performance of the rubber joint. Rubber joint seal is usually made of plastic, so when choosing the structure and performance of rubber joints, the fire resistance and fire prevention of rubber joints, especially in the petroleum, chemical, metallurgical and other sectors using flammable and explosive media in the equipment and piping systems of rubber joints, more attention should be paid to fire resistance and fire prevention.

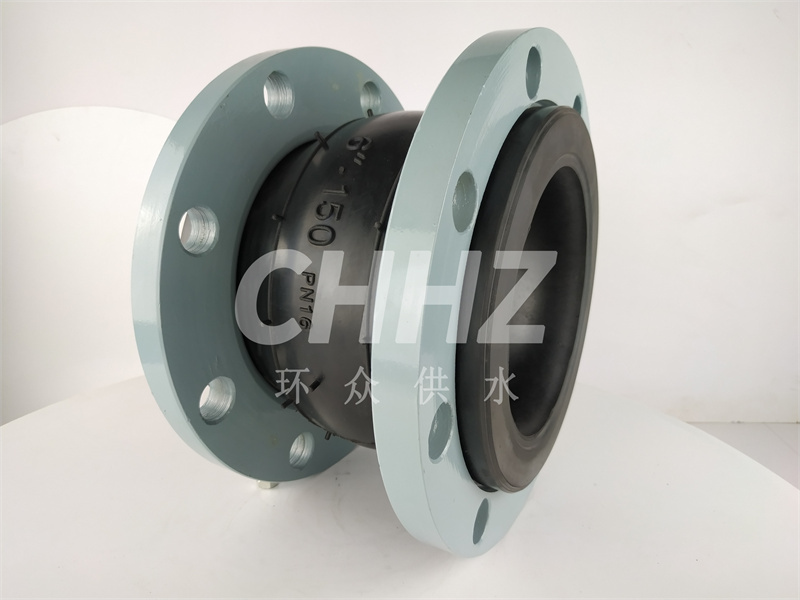

The most critical factor that determines the quality of rubber expansion joints is the rubber material, and good rubber material can be made into good rubber joints. Some rubber joints have poor damping performance, some will crack and age more seriously after using for a period of time. These are caused by poor quality rubber. You can first look at the color of the rubber under the sun or light. A particularly bright one is not necessarily a good rubber sphere. A good rubber sphere is of course bright in black, a natural rubber color.

How much pressure the sphere can withstand, due to the flow rate of materials, the inner diameter of the rubber, etc., is to withstand some pressure, and this pressure has a positive pressure and negative pressure. According to their own needs to choose the rated pressure is greater than the working pressure used in practice, to avoid damage to the sphere.

Also according to their own work when the circulation medium to choose different rubber materials, there are natural rubber, butyl rubber, butyl rubber, nitrile rubber, EPDM rubber, neoprene, silicone rubber, fluorine rubber and so on. They are heat-resistant, acid-resistant, alkali-resistant, corrosion-resistant, wear-resistant, oil-resistant and other functions. Choosing the right rubber material can reduce the corrosion degree of the rubber to prolong the service life of the rubber joint.

The length of rubber, too long rubber is bound to be bent in use, which will increase the pressure at the bend of the pipe body when transporting the medium, and will also cause certain damage.