Introduction to the reliability and compensation capacity of the compensator

The reliability of the compensator is composed of several aspects such as design, manufacture, installation and operation management. Reliability should also be considered from these aspects. Compensator material selection of the bellows used in the heating pipe network, in addition to the working medium, working temperature and external environment should be considered, but also the possibility of stress corrosion of the compensator, water treatment agents and pipe cleaners on the impact of materials, etc., and on this basis, combined with the bellows material welding, molding and the performance to price ratio of materials, preferably selected economical and practical bellows compensator production materials.

Life is the compensator in a given working condition full rated displacement guaranteed fatigue times. Because of more factors affecting the life, the determination of the life of the compensator should be very strict, in addition to the design calculation to give sufficient coefficient, but also through the experiment to ensure. The rated life given by the compensator is guaranteed by 2 to 5 times of the average experimental life.

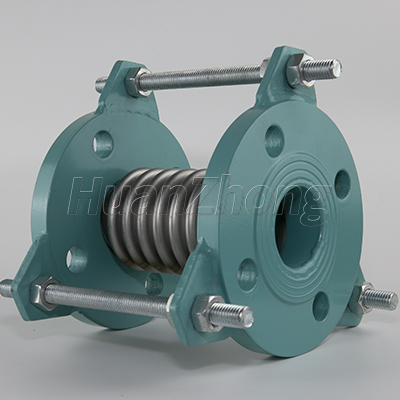

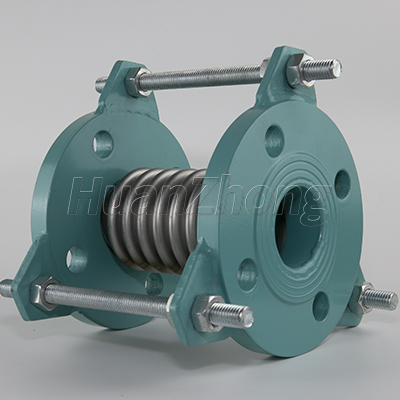

The compensation capacity of the compensator is derived from the elastic deformation of the bellows, in tension, compression, bending and their combined deformation. The size of the compensation capacity of the compensator is determined by the designer according to the need, reflected in the product that is the specified rated compensation, which means that the large compensation capacity under the conditions. Different types of compensator compensation forms are different, mainly axial, transverse, angular and their combination of compensation.

The fatigue damage of the compensator refers to the phenomenon that the bellows produces cracks and loses its sealing effect after a period of time under the action of cyclic load. In the valve, the bellows compensator not only needs to withstand the working pressure of the fluid medium, but also needs to withstand the valve opening, closing process of the tube to produce tensile and compressive stress. These factors change periodically with time, so fatigue damage mostly belongs to multi-axis fatigue. Compensator fatigue life is a very important performance parameter. With the development of computer technology and finite element theory of the mature and perfect, the use of wired elements on the bellows compensator life became possible.